BOROFLOAT® 33 – Borosilicate glass from SCHOTT

Special Properties

- High transmission of visible and infrared light

- Extensive operating temperature range:

– up to 450 °C at permanent load

– up to 500 °C at temporary load (< 10 h) - High UV transparency

- Resistant against strong acids, bases, and organic substances

- High thermal shock resistivity

- Colorless and clear appearance

- Low self-fluorescence

- Relatively low alkali content in the glass composition

- Low specific weight

- High scratch and abrasion resistance

- High elasticity and mechanical strength

- Superior flatness resulting from a unique micro-float manufacturing process

- Low coefficient of thermal expansion similar to that of silicon wafers used for anodic bonding

- Low microroughness

Typical Applications

- Industrial optics for increased operating temperatures

- Medical and biotechnology applications

- Wafer glass for anodic bonding processes

- Flat glass substrates for dielectric filters

- Glass components for lighting systems

- Front glass for high-power floodlights

- Substrates for lighting filters

- Photovoltaic applications

- Sight-glass windows

- Fiber optic devices

- Glass covers for sensors

- Laboratory glass equipment

- Glass components for environmental technology

- Microscope slides for chemical analysis and medical purposes

- Substrate glass for electronics

- Laser applications

- Windows used in harsh environments

- Neutron absorbers

- Glass packaging for optoelectronic components

- Analytic systems

- Measuring and sensor devices

Related glass types

- MEMpax®

(thin borosilicate glass from SCHOTT) - Quartz Glass

(optical-grade fused silica)

Get a quote

![]() 48-hour express service

48-hour express service

BOROFLOAT® is a high-quality, clear-transparent glass that offers excellent and uniform optical transmission from the visible to the infrared spectrum. SCHOTT manufactures this borosilicate glass using a unique micro-float process. This technique provides exceptional flatness, high surface quality, low microroughness, and superior material homogeneity. Furthermore, BOROFLOAT® glass features low self-fluorescence over a broad light spectrum.

BOROFLOAT® offers an exceptionally high optical quality for a flat glass, facilitating a full scope of applications in industrial optics, optoelectronics, photonics, analytics, and lighting technology. It can be used as a base glass for optics and often does not require expensive additional mechanical polishing processes. SCHOTT's BOROFLOAT® flat glass provides capabilities required by substrate materials used for coated optics like mirrors, filters, anti-reflection coatings, or, in some instances, even laser optics. It is ideal for producing window optics, substrates, glass wafers, and a wide range of other plane optical components. BOROFLOAT® is also well suited for lighting technology and numerous applications in electronics. For example, we use BOROFLOAT® glass as a coating substrate for lighting-filter products like our cold mirror and hot mirror series, and we use it as a glass substrate for our high-reflection dielectric mirror optics.

Due to its remarkable thermal capabilities, BOROFLOAT® is a perfect and economical glass material for many applications at an increased operating temperature. It is heat-resistant and can permanently work at up to 450 °C. In the short term (< 10 h), it can withstand up to 500 °C.

BOROFLOAT® has a small thermal expansion coefficient similar to that of silicon, making glass wafers of SCHOTT's borosilicate glass ideal for anodic bonding applications. BOROFLOAT® has almost the same thermal expansion and mechanical density as PYREX® glass, a long-time standard material for producing glass wafers. Many customers today use BOROFLOAT® to substitute PYREX® glass wafers because CORNING discontinued PYREX® flat glass many years ago.

| Figure: CNC-manufactured high-temperature window optics for a micro-reactor made of BOROFLOAT® glass from SCHOTT. |

BOROFLOAT® has virtually the same glass composition as DURAN®, a SCHOTT glass product mainly used for laboratory equipment. Consequently, the glass is resistant to water, neutral, saline, and acidic solutions, as well as iodine, chlorine, bromine, and organic substances, even over long periods and temperatures above 100 °C. BOROFLOAT® exceeds the chemical strength of many other glass materials and most metals.

Acids and alkalis can only dissolve small amounts of ions from BOROFLOAT® glass. Therefore, BOROFLOAT® does not falsify the measurement results in analytical technology known from soda-lime float glass materials. These properties enable the use of BOROFLOAT® glass in numerous medical technology and analytical applications.

The mechanical properties of BOROFLOAT® glass exceed those of soda-lime glass and most other borosilicate glass materials. Moreover, the abrasion resistance of BOROFLOAT® significantly surpasses that of ordinary soda-lime float glass. We manufacture all kinds of glass parts from BOROFLOAT®. If you require further assistance regarding our manufacturing capabilities, please do not hesitate to contact us.

To get a quotation for a window, substrate, or any other component made of original SCHOTT BOROFLOAT® 33 glass with individual dimensions, please use the button below or choose a thickness in the selection table.

Specifications

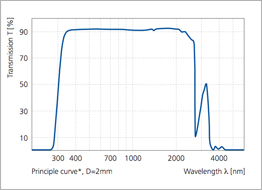

UV-VIS-IR-transmittance

at 2 mm thickness

Enlarge the full spectrum curve

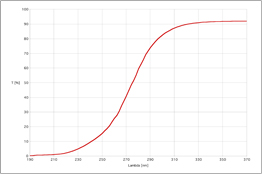

UV transmittance at 0.7 mm thickness

Show curve for 0.7 mm glass thickness

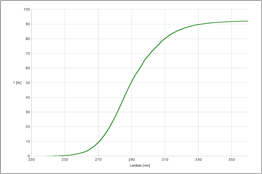

UV transmittance at 3.30 mm thickness

Show uv transmission at 3,3 mm thickness

Please contact us for the measured transmittance curves of BOROFLOAT® at other glass thicknesses.

Standard Thicknesses

Please click on a glass thickness to request a quote.| Thickness (mm) | Tolerance | |

|---|---|---|

| 0.70 | ±0.05 | ✔ |

| 1.10 | ±0.05 | ✔ |

| 1.75 | ±0.20 | ✔ |

| 2.00 | ±0.05 | ✔ |

| 2.25 | ±0.20 | ✔ |

| 2.75 | ±0.10 | ✔ |

| 3.30 | ±0.20 | ✔ |

| 3.80 | ±0.20 | ✔ |

| 5.00 | ±0.20 | ✔ |

| 5.50 | ±0.20 | — |

| 6.50 | ±0.20 | ✔ |

| 7.50 | ±0.30 | — |

| 8.00 | ±0.30 | — |

| 9.00 | ±0.30 | — |

| 11.0 | ±0.30 | — |

| 13.0 | ±0.30 | — |

| 15.0 | ±0.30 | — |

| 16.0 | ±0.50 | — |

| 18.0 | ±0.50 | — |

| 19.0 | ±0.50 | — |

| 21.0 | ±0.70 | — |

| 25.4 | ±1.00 | — |

| The thicknesses marked with "✔" are also available within our 48-hour express service. | ||

Optical Properties

- Abbe constant ve: 65.41

- Dispersion nF - nC : 10-4 71.4 × 10-4

- Stress optical coefficient K: 4.0 × 10-6 mm2 N-1

| Index of Refraction | ||

|---|---|---|

| Wavelength (nm)

|

Refractive Index

|

|

ng |

435.8 |

1.480 |

nF' |

479.9 |

1.477 |

ne |

546.1 |

1.473 |

nd |

587.6 |

1.471 |

nD |

589.3 |

1.471 |

nC' |

643.8 |

1.470 |

nC |

656.3 |

1.469 |

| Guide values, not guaranteed values. | ||

Mechanical Properties

- Density: 2.2 g/cm3 (25 °C)

- Young's modulus E: 64 kN/mm2

(according to DIN 13 316) - Poisson's ratio μ: 0.2 (according to DIN 13 316)

- Shear modulus σ: 25 MPa

(according to DIN 52 292 T 1) - Knoop hardness HK0.1/20: 480

(according to ISO 9385)

Thermal Properties

- Coefficient of thermal expansion:

3.25 × 10-6/K (20–300 °C) (according to ISO 7991) - Specific heat capacity cP: 0.83 kJ × (kg K)-1

- Specific heat conductivity:

1.2 W (m × K)-1 (90 °C) - Transformation temperature Tg: 525 °C

- Viscosities:

- Working Point (104 dPa): 1270 °C

- Softening Point (107.6 dPa): 820 °C

- Annealing Point (1013 dPa): 560 °C

- Strain Point (1014.5 dPa): 518 °C

- Maximum operating temperatures σmax :

(only valid considering the following RTG and RTS values)

- for short-term load 500 °C (< 10 h)

- for long-term load 450 °C (≥ 10 h)

- Resistance to thermal gradients (RTG):

- 110 K (< 1 h)

- 90 K (1-100 h)

- 80 K (> 100 h)

(Testing method description on demand)

- Resistance to thermal shock (RTS):

- 175 K (at thickness ≤ 3.8 mm)

- 160 K (at thickness = 5.0–5.5 mm)

- 150 K (at thickness = 6.5–15.0 mm)

- 125 K (at thickness > 15.0 mm)

(Testing method description on demand)

Chemical Properties

- Hydrolytic resistance:

- Class HGB 1

(according to ISO 719 / DIN 12 111) - Class HGA 1

(according to ISO 720)

- Class HGB 1

- Acid resistance:

- Class 1 (according to ISO 1776 / DIN 12 116)

- Alkali resistance:

- Class A2 (according to ISO 695 / DIN 52 322)

- Chemical Glass Composition:

- 81% SiO2

- 13% B2O3

- 4% Na20 / K2O

- 2% Al2O3

| Chemical Durability | ||

|---|---|---|

| Solution | Reaction time/

Temperature |

Weight loss

(mg/cm2) |

| 5 Vol.-% HCl | 24 h at 95 °C |

<0.01 |

| 0.02 n H2SO4 | 24 h at 95 °C |

<0.01 |

| H20 | 24 h at 95 °C |

<0.01 |

| 5% NaOH | 6 h at 95 °C |

1.1 |

| 0.02 n NaOH | 6 h at 95 °C |

0.16 |

| 0.02 n Na2CO3 | 6 h at 95 °C |

0.16 |

| 10% HF | 20 min at 23 °C |

1.1 |

| 10% NH4F x HF | 20 min at 23 °C |

0.14 |

Electrical Properties

| Dielectric constant (permittivity) εr and loss tangent |

||

|---|---|---|

Frequency (GHz) |

Dielectric Constant |

Loss tangent tan(δ) [10-4]

|

0.001 |

4.6 |

48

|

1 |

4.4 |

51

|

2 |

4.4 |

56 |

2.45 |

4.4 |

58 |

5 |

4.4 |

66 |

10 |

4.4 |

75 |

15 |

4.4 |

82 |

24 |

4.4 |

91 |

77 |

4.4 |

127 |

110 |

4.4 |

152 |

- Specific AC-volume resistivity ρD (Ω x cm) at 50 Hz:

- 1.0 × 108 (250 °C)

- 3.2 × 106 (350 °C)

Note: Further SCHOTT glass materials like the brand glasses MEMpax®, ultrathin D263 T glass, AF 45, AF 32® eco, ultrathin AS 87 eco, N-BK7, SUPREMAX®, DURAN®, and ZERODUR® transparent glass ceramic are part of the extensive delivery program of our company. Please follow the links or contact us for further information about these SCHOTT glass solutions.

If you need additional information about SCHOTT BOROFLOAT® 33 glass or our manufacturing capabilities, please do not hesitate to send your information request.

BOROFLOAT® 33 is a registered trademark of SCHOTT.

All data and specifications given are average guide values and are not guaranteed. Moreover, please consider the “Notes on Specifications”.© 1994 – 2025 Präzisions Glas & Optik GmbH

Last update: November 18, 2025