Anti-Reflection Coatings

Anti-Reflective Coatings for Technical Glass

ARC series

Special Properties

- Significant reduction of reflected light from glass surfaces

- Excellent light transmission in the visible range

- Interference-based optical coating

- Suppression of ghost images

- Enhanced imaging and contrast

- Broadband, multi-layer design

- Low absorption design

- High abrasion resistance and coating adhesion

- Refractive index of the layer system optimally matched to the substrate glass

- Available on glass thicknesses as low as 0.7 mm

Typical Applications

- Anti-reflection coatings for optics in optical systems

- Sensor covers

- AR coatings on scanner front glasses

- Laser optics

- Windows for measuring instruments

- Low-reflection sight glasses

- Automotive cockpits

- Windows for camera housings

- Optics for medical devices

- Microelectronics and photolithography

Other AR Coating Variants

- Oleophobic AR coating

(Fingerprint-, liquid-, and dirt-repellent)

High-Performance Anti-reflection coatings

Anti-reflection coatings (also called anti-reflective coatings) consist of precision-engineered thin-film layers coated onto technical optical glass surfaces. These coatings minimize unwanted surface reflections and maximize transmission across visible wavelengths. The ARC series is developed specifically for industrial and scientific applications requiring consistent low reflectance and high transmission in a wide spectral range.

Improved Optical Transmission

Our ARC series delivers high efficiency and optical performance. Each ARC multilayer coating is composed of multiple thin layers, each with a different refractive index. These layers are alternately applied to the glass surfaces. The thickness, material, and refractive index of each layer are chosen to produce destructive interference for reflected light and constructive interference for transmitted light. The result is a broadband, efficient anti-reflective layer system with outstanding light transmission.

|

|

Low Reflection and Ghost Image Reduction

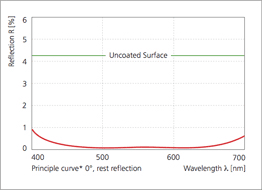

All anti-reflection coatings in our ARC series are deposited on high-quality glass materials that provide excellent performance and transmission in the visible wavelength range. Uncoated glass reflects about 4.25% of visible light per surface. Where traditional single-layer anti-reflective coatings still have a residual reflection of 1-2% per side, our multilayer ARC system achieves a residual reflection of less than 0.2% per surface in some parts of the visible spectrum. Additionally, our AR coatings effectively suppress ghost images, which occur on uncoated glass due to the superimposition of the transmitted image with secondary reflections.

AR Coatings for Precision Optics

Anti-reflection-coated glass for the visible and near-infrared spectra is used in many everyday applications. For example, most eyeglass lenses, magnifying glasses, camera lenses, and display screens incorporate basic AR layers. But especially in technical optics, anti-reflection coatings are indispensable and generally need to be even more effective than in consumer applications, as uncoated glass or lenses can distort measurement results, impair the accuracy of sensors, or blur transmitted images. In those cases our ARC coatings are typically an ideal solution. Our ARC layers are applied to flat, mirror-grade selected float glass substrates. The ARC-B variant uses equally high-quality selected borosilicate glass. Each anti-reflection coating is optimally adapted to the refractive index of the substrate material used.

Customized Anti-Reflective Coatings

We are not limited to the standard coatings presented on this page. We can produce custom anti-reflective coating stacks optimized for special wavelength ranges or angles of incidence. Our anti-reflective layer systems can be vacuum deposited onto other suitable glass types or virtually any optical element, provided the order quantity meets minimum requirements. Custom coatings for lenses or lens assemblies are possible on a batch basis. Optimizations for additional wavelength ranges, angles of incidence, or specialized laser coatings can also be provided.

Ordering Information and Standard Dimensions for ARC Anti-Reflective Coatings

We are not restricted to fixed sizes. Our company specializes in manufacturing and delivering custom dimensions with lead times typically similar to stocked parts.

To receive a quote for our ARC glass with anti-reflection coating in custom dimensions, please consider using the button below or selecting a material from the table.

![]() 48-hour express manufacturing

48-hour express manufacturing

Performance Specifications for

ARC

Anti-Reflection Coatings

Residual reflection of the ARC

compared to uncoated glass surfaces

Standard Thicknesses

| Thickness (mm) | Tolerance | |

|---|---|---|

ARC: Double-side broadband AR coated selected float glass |

||

| 0.70 | ± 0.05 | ✔ |

| 1.10 | ± 0.10 | ✔ |

| 2.00 | ± 0.20 | ✔ |

| 3.00 | ± 0.20 | ✔ |

ARC-1S: Single-side broadband AR coated selected float glass |

||

| 2.00 | ± 0.20 | ✔ |

ARC-B: Double-side broadband AR coated borosilicate glass |

||

| 2.00 | ± 0.20 | ✔ |

| 3.30 | ± 0.20 | ✔ |

Other glass thicknesses are obtainable on request. |

||

| The thicknesses marked with ✔ qualify for 48-hour express manufacturing. | ||

The ARC coatings are applied via high-vacuum deposition with precisely controlled layer thickness and refractive index. Layer materials are selected for optimal destructive interference to minimize reflection across the visible spectrum on technical optical float and borosilicate glass substrates.

Spectral Specifications

- Absolute Reflectance (Rabs) ≤ 0.6% per optical surface from 450 to 650 nm for unpolarized light at normal incidence (0°).

- Average Reflectance (Ravg) < 0.5% per optical surface from 430 to 660 nm for unpolarized light at angles of incidence between 0° and 15°.

- Optimizations for other wavelengths and custom designs are possible upon request.

Flatness

- Flatness depends on the type of glass and its thickness.

Surface Quality

- Better than 80-50 scratch & dig (MIL-0-13830A)

- Other specifications are available upon request

Other Specifications

- Adhesion according to MIL-C-675 C

- Abrasion resistance according to MIL-M-13508 C

Note: We are often asked whether we apply anti-reflection coatings to eyeglass lenses. Such AR coatings for eyewear are not part of our manufacturing program. We specialize exclusively in coating technical glass for industrial and scientific applications.

All details and specifications given are mean reference values and are not guaranteed. Please consider our Notes on Specifications.

© 1994–2026 Präzisions Glas & Optik GmbH

Last update: December 17, 2025