Custom Optical Coatings

Overview of our coating capabilities and types of thin films

We manufacture custom optical thin film coatings to our customers' exacting requirements in addition to our numerous standard thin-film components. The following overview presents a summary of the most common types of optical layers we produce. We coat these optical coatings mainly on flat optical substrates. Still, depending on the application's details, it is also part of our capabilities to deposit optical lenses and precision optics. Please follow the links to our coating inquiry form to conveniently enter the characteristics of your required customized coatings and to place a request:

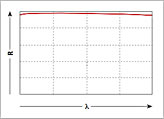

Metallic and dielectric mirror coatings

Metallic and dielectric mirror coatings are mainly reflective and offer high imaging quality. They are based on all-dielectric or metallic layers like aluminum, enhanced aluminum, silver, enhanced silver, gold, chrome, copper, or platinum. Optical reflection, incidence, polarization, and other characteristics are adjusted to meet custom requirements. In addition to our standard mirror coatings, you can use our custom optics inquiry form to conveniently request a quotation for your customized mirror coating design.

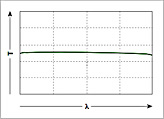

Beamsplitters and partially transmitting coatings

This kind of optical coating is used for the neutral splitting of light, laser radiation, or the defined damping of a light source. Beamsplitters can either have dielectric or metallic coating systems. The dividing ratio is adjusted to the customer's specification by modification of the layers. The backside can be anti-reflection coated to minimize unwanted secondary reflections and prevent energy loss. In case you can't work with our standard beamsplitter coatings, please use our custom thin-film coatings' inquiry form to conveniently receive a quotation for your customized beamsplitter design.

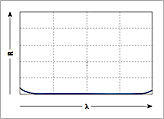

Single and multilayer anti-reflection coatings

These thin-film coatings minimize or eliminate unwanted reflections. Moreover, they can prevent ghost images or double laser beams from uncoated glass surfaces. The optical design is optimized for single wavelengths or a wide wavelength range (broadband AR coating) and for low surface reflection. The available transmitted light often increases by the same amount as the residual reflectance decreases.

Besides our anti-reflection coating standards, you have the opportunity to conveniently request a quotation for a custom coating by using our coating inquiry form.

Cold mirrors and coatings for lighting applications

Cold mirrors are based on dielectric optical coatings with high reflection in the visible range and excellent transmittance in the infrared spectrum. A cold mirror is mainly used to efficiently filter out heat or IR radiation from a light beam or an optical system. The cut-on and cut-off wavelengths and the range of reflection can be shifted or modified according to the customer's specific requirements.

Besides our standard cold mirrors, you can use the coating inquiry form to get a price for your custom-designed cold-mirror optics conveniently.

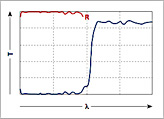

Hot mirrors and heat-reflecting coatings

Such dielectric optical filters with high transmission in the visible and high reflection in the infrared are predominantly used to block heat and IR radiation. These filter coatings can also be used as reflectors for the infrared spectrum, such as NIR laser diodes (eye-tracking, e.g.), while being transparent in the visible. We can customize the cut-off wavelength, optical transmission, and reflection range of the filters. In addition to our heat-reflecting standard hot mirrors, you can use our coating request form to conveniently get a price quote for your custom hot mirror coating design.

ITO-coatings

Electrically conductive and transparent layers

These electrically conductive coatings have excellent optical transmission in the visible and defined electrical sheet resistance. The surface resistance and transmission depend on the film thickness and can both be customized. Sheet-resistances may be in the range from 5 Ω/sq. up to 10 kΩ/sq. ITO-coatings with low surface resistivity are often used as infrared reflecting optics. In addition to our standard ITO-coated materials, you can use our coating inquiry form to get a quotation for your customized ITO-coated glass conveniently.

Other optical coatings

We are not limited to the coating categories and capabilities described before. In addition to the coatings listed, we are manufacturing the following additional thin-film coatings to customer specifications:

- Dichroic precision beamsplitter coatings

- Color filters

- Conversion filters

- Dichroic color filters

- RGB-filter sets

- Coatings for ultraviolet light

- Band pass filters

- Short pass filters

- Long pass filters

- Coatings for lenses

If you need a quotation for a custom coating, please let us know your requirements. To immediately process your inquiry, we need to have the following specifications and information:

- The desired transmission(s) & reflection(s) in percent

- Specifications of all relevant wavelength ranges in nm

- The angle of incidence or range of angles

- The desired substrate material, dimensions, and required mechanical and optical precision

- Any temperature requirements and other specifications that are relevant for your application

- The required quantity

If you have any further questions about our coating capabilities or need engineering assistance in designing your custom coating, please do not hesitate to contact us.

© 1994 - 2026 Präzisions Glas & Optik GmbH

Last update: January 29, 2026