Hot Mirrors – IR-Reflection Filters

SIR-Series

Special Properties

- High VIS-transmission

- Efficient heat management and thermal energy blocking

- Optimized for 0° angle of incidence

- High infrared reflectivity up to 1100 nm

- High color neutrality

- All dielectric, metal-free layer design

- Operating temperature up to 350 °C

- Borosilicate glass substrate

- Borosilicate glass substrate with high optical quality

- Works on the reverse principle of SHD cold mirror

Typical Applications

- IR-cut filters for CCD camera chips

- Heat protection filters for light sources

- IR-reflection optics in lighting systems

- Mirror for IR laser diodes

- Measurement and sensor technology

- Automotive lighting applications

- Fiber protection filters

- Detector trimmers

- Mirror for eye-tracking systems

- Laser beam injectors

- Thermal energy control in projectors

Related Products

- Heat Absorbing Filters from SCHOTT

(KG1, KG2, KG3, KG4, & KG5) - SIR-IR Series

(Hot mirror with extended reflection range) - SHD-Series

(Dichroic cold mirror)

Hot mirrors are designed to reflect unwanted infrared radiation (IR) while transmitting most visible light. This selective dichroic reflection and transmission capability is achieved through carefully tailored optical coatings deposited on optical substrates. By effectively reflecting the IR wavelengths and allowing visible light to pass through, the SIR mirror prevents the excessive heating of target objects or sensitive components within optical systems. It operates on the opposite optical principle of cold mirrors. Since it reflects infrared light and filter it out of the beam path, it is called a hot mirror, heat-reflecting filter, or heat-reflection mirror. All these terms are commonly used.

Our SIR offers a substantial advantage over standard hot mirrors and heat-absorbing filters. It provides higher, more color-neutral transmission of visible light and reflects near-infrared thermal radiation up to 1100 nm much more efficiently. Its all-dielectric filter design, combined with thermally resistant borosilicate glass, allows operation at temperatures up to 350 °C—ideal for high-energy lighting systems.

Our SIR offers a substantial advantage over standard hot mirrors and heat-absorbing filters. It provides higher, more color-neutral transmission of visible light and reflects near-infrared thermal radiation up to 1100 nm much more efficiently. Its all-dielectric filter design, combined with thermally resistant borosilicate glass, allows operation at temperatures up to 350 °C—ideal for high-energy lighting systems.

SIR mirrors are ideal for themal energy management in optical systems. Unlike absorption-based filters, hot mirrors remain cooler since they reflect infrared energy back to the light source instead of absorbing it. This efficiently blocks and reflects thermal energy before it enters the optical system.

In addition to the applications described above, there are also purely optical tasks for our SIR mirrors. For example, they are often used in front of digital camera chips as detector trimming optics to prevent image sensor saturation from near-infrared light. CCD camera sensors are typically highly sensitive to this spectral range.

The non-metallic construction of the SIR hot mirrors provides excellent thermal and humidity resistance. Their thin film is optimized for optimal performance at 0° angle of incidence. When a slight shift of the cut-off wavelength is acceptable, the SIR can also be used at 45° incidence. At this angle, it still transmits most of the visible spectrum, and the IR-reflected image maintains good optical quality. As a result, many customers use our SIR hot mirrors for eye-tracking and IR laser beam injection systems. This approach can significantly reduce costs, particularly for smaller quantities, as no expensive customization is necessary. If you want to operate our SIR hot mirrors at an angle deviating from 0°, please inquire by email or via our support form to obtain more information. We can provide spectral curves for 45° or other angles upon request.

We can tailor the SIR's transmission and reflectivity by adjusting the coating layers. The same applies to the optics' optical cut-on and cut-off filter wavelengths. Customized cut-on and cut-off wavelengths are also available. Please use our inquiry form to request a quote for your customized optics.

Please select a thickness from the table or use the button below to request a quotation for our SIR hot mirrors with your individual dimensions.

Specifications

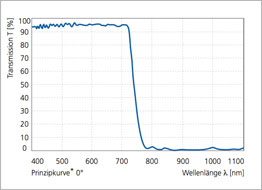

SIR hot mirror transmittance spectrum

at 0° angle of incidence

Click to enlarge the curve for detailed view

Standard Thicknesses

| Thickness (mm) | Tolerance | |

|---|---|---|

| 1.10 | ±0.10 | ✔ |

| 1.75 | ±0.20 | ✔ |

| 3.30 | ±0.20 | ✔ |

| Custom thicknesses upon request. | ||

| ✔ Indicates the availability for 48-hour express manufacturing. | ||

Construction

- Multilayer, all-dielectric filter coating

- Optimized for 0° angle of incidence

- Custom cut-on and cut-off wavelengths available

Substrate

- BOROFLOAT® (density 2.2 g/cm³ (25 °C))

- Other substrate options upon request

Operating Temperature

- Up to 350 °C with uniform heating

Optical Flatness

- Varies with substrate type and thickness

- Specified flatness upon request

Surface Quality

- Typical 80-50 scratch-dig (MIL-O-13830A)

- Other surface qualities upon request

Other Properties

- Adherence according to MIL-C-675 C (tape test)

- Abrasion resistance per MIL-M-13508C

Note: For optics with the reverse functional characteristics of our hot mirrors, please visit our cold mirror spec sheet. For reflectivity beyond the near-infrared range, please look at the data sheets on our SEA-NIR, SEA-UV, and ITO-coated materials.

All data and specifications given are average guide values and are not guaranteed. Moreover, please consider the “Notes on Specifications”.

© 1994 – 2026 Präzisions Glas & Optik GmbH

Last update: November 7, 2025