MEMpax® – High-quality borosilicate thin glass

Special Properties

- Minimal thickness tolerance

- Excellent surface quality and flatness

- Low CTE similar to the one of silicon

- High operating temperature

- Low autofluorescence

- High UV transparency

- Superb chemical resistance

- Good electrical insulation

- Low specific weight

- Very low micro-roughness

Typical Applications

- Glass wafers for anodic bonding

- Micro-Electro-Mechanical Systems (MEMS)

- Biotech research

- Sensor applications

- Chemically resistant microscope slides and cover-slips

- Thin glass wafer applications

Related glass types

- BOROFLOAT® 33

(borosilicate glass from SCHOTT) - D 263 T

(thin and ultra-thin SCHOTT borosilicate display glass) - AS 87 eco

(ultra-thin aluminosilicate glass from SCHOTT) - AF 32® eco

(alkali-free alumina-borosilicate glass from SCHOTT) - AF 45

(modified borosilicate display glass from SCHOTT) - 0211

(alkali-reduced borosilicate thin glass from CORNING) - Selected float glass

(iron-reduced soda-lime thin glass)

Request for Quotation

![]() 48-hour express service

48-hour express service

MEMpax® is a thin glass with the exceptional technical properties of borosilicate glass. The material features very smooth, high-quality surfaces and excellent flatness. A sophisticated fire polishing process enables the thin glass to have an extremely low micro-roughness, typically less than 0,8 nm. The high surface quality and flatness of MEMpax® permit direct use without the necessity of additional mechanical polishing. The coefficient of expansion of MEMpax® is close to that of silicon, making this material a perfect choice for wafer applications in anodic bonding processes. Further typical uses for the high purity borosilicate-thin glass are MEMS applications (Micro-Electro-Mechanical Systems) and biotechnology applications. MEMpax® is a registered trademark of SCHOTT.

To receive a quotation for wafers, windows, or substrates made of MEMpax® materials with specific dimensions, please select a product from the table or click the button below.

Note: If you plan a sizeable serial production but none of the listed currently available glass thicknesses in the table match the technical requirements of your application, please get in touch. During the introduction stage of MEMpax®, we can ask SCHOTT to melt the glass thickness you need in the future. Of course, this requires an amount of material large enough.

Specifications

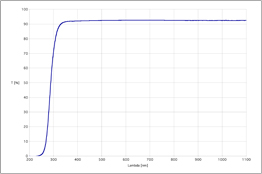

VIS-NIR Transmission

Transmission of MEMpax at 200–1100 nm

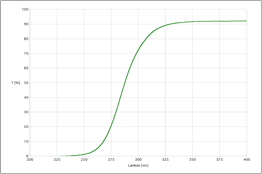

UV-Transmission at 0.5 mm

UV-Transmission of MEMpax at 200–400 nm

Standard Thicknesses

(Please click on a glass thickness to request a quote)Thickness (mm) |

Tolerance |

|

|---|---|---|

| 0.200 | ±0.012 | ✔ |

| 0.300 | ±0.012 | ✔ |

| 0.400 | ±0.015 | ✔ |

| 0.500 | ±0.018 | ✔ |

| Materials marked with ✔ are available within 48–h Express Service. | ||

If you need a glass with a larger thickness, SCHOTT BOROFLOAT® 33 is an alternative because it has almost the same thermal expansion, refractive index, and density as MEMpax®. BOROFLOAT® 33 is available in an extensive range of thicknesses from 0.7 to 25.4 mm. |

||

Optical

- Abbe Constant ve: 65.4

Index of Refraction of MEMpax |

||

|---|---|---|

| Title

|

Wavelength (nm)

|

Refractive Index

|

ng |

435.8 |

1.4803 |

nF' |

479.9 |

1.4768 |

ne |

546.1 |

1.4732 |

nd |

587.6 |

1.4715 |

nD |

589.3 |

1.4714 |

nC' |

643.8 |

1.4696 |

nC |

656.3 |

1.4693 |

Mechanical

- Density: 2.22 g/cm3 (cooling rate 40 °C/h)

- Young's modulus E: 62.7 kN/mm2

- Poisson's ratio μ: 0.196

- Torsion modulus: 26.2 kN/mm2

- Knoop hardness HK0.1/20: 430

Thermal

- Average coefficient of thermal expansion:

3.3 × 10-6/K (20 °C ; 300 °C)

(static measurement) - Specific heat capacity cP: 0.82 kJ (kg × K)-1

- Specific heat conductivity: 1.12 W (m × K)-1 (90 °C)

- Transformation temperature Tg: 532 °C

- Viscosities:

- Working Point (104 dPa): 1284 °C

- Softening Point (107.6 dPa): 831 °C

- Annealing Point (1013 dPa): 570 °C

- Strain Point (1014.5 dPa): 528 °C

Chemical

- Hydrolytic Resistance:

- Class HGB 1 (according to ISO 719)

- Acid Resistance:

- Class S 1 (according to DIN 12 116)

- Alkali Resistance:

- Class A 2 (according to ISO 695)

Electrical

Dielectric Constant (permittivity) εr |

||||||

|---|---|---|---|---|---|---|

| Frequency in GHz | 0.001 |

1.0 |

2.0 |

5.0 |

24 |

77 |

4.8 |

4.4 |

4.5 |

4.4 |

4.4 |

4.5 |

|

Loss Tangent tan(δ) x 10-4 |

||||||

|---|---|---|---|---|---|---|

| Frequency in GHz | 0.001 |

1.0 |

2.0 |

5.0 |

24 |

77 |

37.6 |

58 |

62 |

73 |

130 |

140 |

|

- Specific AC-Volume Resistivity ρD (Ω x cm):

- 1.18 × 108 (250 °C)

- 4.24 × 106 (350 °C)

© 1994 – 2026 Präzisions Glas & Optik GmbH

Last update: December 8, 2025