Optical Quartz Glass – UV-Grade Fused Silica

Special Properties

- UV transmission >80% at 185 nm

- High purity (>99.99% SiO₂)

- Excellent optical quality

- Temperature resistance up to 1000 °C

- Low thermal expansion

- Amorphous (non-crystalline) structure

- Crystal-clear appearance

- High thermal shock resistance

- Outstanding chemical resistance

- High hardness and good scratch resistance

- Good electrical insulation

- Low fluorescence

- Made by a flame hydrolysis process

- High mechanical strength

- Machinable by CNC cutting, grinding, and polishing

Typical Applications

- UV and laser optics

- Substrates for mirrors and filter coatings

- Measuring instruments for the UV spectrum

- Wafers for the semiconductor industry

- Photomask blanks

- Microscope slides and cover glasses for medical use

- Optics for high-temperature equipment

- Laboratory test glasses

- Sample-storage solutions

- Space and aviation applications

Related Glass Types

Optical Quartz Glass — UV-Grade Fused Silica

Synthetic UV-grade fused silica is the most commonly used quartz glass type for optics. This clear, amorphous glass consists exclusively of silicon and oxygen (SiO₂). Its exceptional purity and homogeneous structure provide the optical quality required for demanding applications in UV spectroscopy, laser systems, and semiconductor manufacturing.

UV Transmission Properties

Because the content of metals or other contaminants that typically absorb UV light is marginal, optical quartz glass offers high transmission at deep ultraviolet wavelengths, which exceeds 80% at 185 nm. The structure of the pure silicon dioxide in the synthetic glass is extremely homogeneous, which further minimizes absorption and scattering losses in the UV. The optical properties of this glass type make it ideal for many applications, especially in the ultraviolet spectrum.

Thermal Properties

Fused silica withstands continuous temperatures up to 1000 °C and tolerates rapid temperature changes. The low coefficient of thermal expansion prevents thermal stress. These properties make it ideal for laser optics, high-temperature applications, and semiconductor processing.

Chemical Strength

Fused silica offers excellent chemical resistance against acids, bases, salt solutions, and reactive gases. Only phosphoric acid and hydrofluoric acid can attack it. This chemical stability ensures long-term durability in corrosive environments.

Electrical Properties

Quartz glass provides high electrical insulation resistance. Because mobile ionic impurities are almost absent, it maintains strong insulation even under elevated thermal conditions. The glass also features a low dielectric constant and maintains stable dielectric properties across a wide spectrum of frequencies, including the gigahertz range. These properties make it a preferred choice for high-voltage, high-frequency, and precision electronic applications.

Optics Made of Quartz Glass

We produce quartz optics for the UV, visible, and infrared spectra, starting with blocks known as boules, which can be selected for minimal inclusions and bubbles. If required by your application, we can achieve refractive index homogeneity as low as ≤ 0.5 ppm. The first step in the fabrication of a quartz optic is cutting the raw glass from the boule. After cutting, the material is shaped and polished to meet specific requirements for flatness and surface quality. This process enables us to manufacture UV-transparent windows, wafers at various thicknesses, slides for microscopy applications, quartz plates, and various other parts daily.

We produce quartz optics for the UV, visible, and infrared spectra, starting with blocks known as boules, which can be selected for minimal inclusions and bubbles. If required by your application, we can achieve refractive index homogeneity as low as ≤ 0.5 ppm. The first step in the fabrication of a quartz optic is cutting the raw glass from the boule. After cutting, the material is shaped and polished to meet specific requirements for flatness and surface quality. This process enables us to manufacture UV-transparent windows, wafers at various thicknesses, slides for microscopy applications, quartz plates, and various other parts daily.

Quartz Glass FAQ

Choosing the right grade

Selecting the appropriate quartz glass for a specific application can be challenging due to the variety of grades and their differing properties and costs. Our FAQ page provides guidance to help you select the appropriate quartz glass grade.

To request a quote for optical quartz glass parts with custom dimensions, please select your desired thickness from the options provided in the table or click the button below.

Specifications

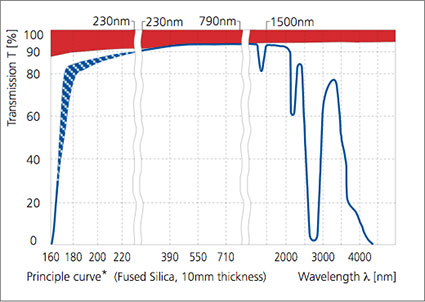

Ultraviolet to infrared transmission

at 160–5000 nm, 10 mm thick

Show full transmission spectrum

Typical transmission

at 185–700 nm, 1 mm thick

Standard Thicknesses

Since fused silica is delivered in unprocessed blocks, there are usually no stock thicknesses. Therefore, a required thickness must typically be specified and manufactured to order. To offer our customers the best possible availability and short delivery times, we continuously grind and polish to some common thicknesses and tolerances, all featuring optical finishes. These thicknesses can therefore be ordered with individually specified dimensions and short delivery times:

Thickness |

Tolerance |

|

|---|---|---|

| 0.175 | ±0.020 | ✔ |

| 0.30 | ±0.050 | ✔ |

| 0.30 | ±0.025 | ✔ |

| 0.50 | ±0.050 | ✔ |

| 0.50 | ±0.030 | ✔ |

| 0.50 | ±0.025 | ✔ |

| 1.00 | ±0.100 | ✔ |

| 1.00 | ±0.025 | ✔ |

| 1.10 | ±0.100 | ✔ |

| 2.00 | ±0.150 | ✔ |

| 3.00 | ±0.200 | ✔ |

| 3.00 | ±0.025 | ✔ |

| If you require other thicknesses, please send us your inquiry. | ||

- T > 80% at 185 nm

- nd = 1.4585

- 2.20 g/cm3

- 74 GPa (typical value)

- Homogeneity classes per specification

- Index homogeneity down to ≤ 0.5 ppm is possible on demand

- SiO₂

- Up to 1000 °C

- ≈ 0.57 × 10-6/K

- Softening point: ≈ 1585 °C

- Annealing point: ≈ 1042 °C

- Strain point: ≈ 893 °C

- εr: 3.9 (500 MHz)

Fused Silica is not the same as Fused Quartz

In addition to the optical grades described on this page, we also offer a less sophisticated quartz glass type known as natural quartz glass or fused quartz. Although the names are similar, the materials are quite different. Fused quartz contains significantly more impurities than synthetic fused silica because it is made by melting naturally occurring quartz crystals from silica sand. While fused quartz glass also has a similarly clear appearance, it transmits less light in the ultraviolet range but is significantly more economical than fused silica. Even if generally not suitable for demanding applications, fused quartz is an ideal choice for industrial high-temperature sight glasses, lighting equipment, and situations that require good chemical strength, heat resistance, and exceptional clarity. For more details, please refer to our fused quartz data sheet.

Raw materials from all leading manufacturers worldwide

Our company works with non-crystalline quartz glasses from nearly all major suppliers in the industry, including CORNING, Heraeus, Tosoh, SCHOTT, Saint-Gobain Quartz, Shin-Etsu, GE Quartz, and many others. If you are looking for special types or require detailed specs, data sheets, and information about the materials we process, please consider using our request form or emailing us.

Note: Single-crystal or crystalline quartz in general is not in our manufacturing range. We only process amorphous glass materials.

All details and specifications provided are average reference values and are not guaranteed. Please refer to the notes on technical specifications for further information.

© 1994–2026 Präzisions Glas & Optik GmbH

Last update: February 05, 2026