D 263 T – Thin and ultra-thin glass

Special Properties

- Low microroughness (typically < 1 nm RMS)

- Excellent flatness

- Clear and practically colorless appearance

- High chemical resistance

- Can be laser-marked

- Very thin standard thicknesses down to 0.03 mm

- Colorless borosilicate glass

- Can be cut with a laser

- Flexible at low thicknesses

Typical Applications

- Cover glass

- Thin glass substrates

- Semiconductor packaging

- Optoelectronic components

- Substrates for optical coatings and filters

- CCD chip covers

- Display glass (PMLCD, AMLCD and TFT displays)

- Electroluminescence display technology

- Microsheets for microscope slides

- Optical windows

- Micro-optics technology

- Ultra-thin glass applications

- Sensor covers

- High-quality coverslips

- Thin glass wafer applications

- Thin glass and microsheet applications

Related glass types

- AF 32® eco (alkali-free alumina-borosilicate thin glass)

- MEMpax® (thin borosilicate glass)

- AS 87 eco (ultra-thin aluminosilicate glass)

- Selected float glass (soda-lime thin glass)

- AF 45 (modified borosilicate display glass)

- 0211 (alkali reduced borosilicate thin glass)

Request for Quotation

![]() 48-hour express service

48-hour express service

D 263 T is a nearly colorless flat borosilicate thin glass made by SCHOTT. The specific properties and an extensive range of standard thicknesses make D 263 T specialty glass ideal for many technical glass applications. Due to the very smooth fire-polished surfaces, D 263 T glass does not require an additional mechanical polishing treatment. D 263 T exceeds the surface quality grade, smoothness, and flatness of most commercial polishing processes. The micro-roughness of the glass surfaces is typically less than 1 nm (RMS).

Measured against optical standards that apply to thicker glass, the possible flatness of ultra-thin glass is limited for technical and physical reasons. The natural weight alone is a limiting factor for the possible flatness of ultra-thin glass. Nevertheless, even low glass thicknesses offer excellent flatness and optical surface quality that mechanically polished thin glass can hardly outperform.

SCHOTT produces D 263 T borosilicate thin glass by melting the purest raw materials. The specialty glass is resistant to chemical attack and offers a high uniform optical transmittance in the visible range. Moreover, D 263 T glass offers higher infrared transmission than most other thin glass materials (you can obtain IR transmittance curves on request).

D263T glass is a perfect choice for display technology, but it is also an ideal substrate for optics, micro-optics, and glass wafer applications. It is often the best glass material for microscope slides and thin or ultra-thin coverslips with high optical quality in research and science.

The glass is nearly always available from us in various extremely thin thicknesses with very low tolerances. Our 48–hour express-service capabilities are also available for this material.

To receive a quote for windows, substrates, or wafer components of original SCHOTT D 263 T or D 263 T eco* borosilicate glass with individual dimensions, please click the button below or select a thickness from the table.

*The D263 T eco materials have been made by SCHOTT using eco-friendly refining agents.

Specifications

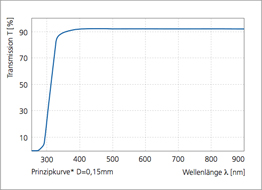

Transmission at 0.15 mm thickness

Enlarge the curve (0.15 mm thickness)

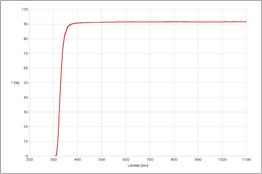

Transmission at 0.7 mm thickness

Enlarge the curve (0.7 mm thickness)

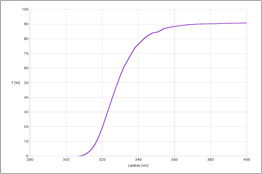

UV-Transmission at 0.7 mm thickness

Enlarge the curve to view uv transmission

Standard Thicknesses

Please click on glass thickness to request a quote.| Thickness (mm) | Tolerance | |

|---|---|---|

| 0.030 | ±0.008 | — |

| 0.050 | ±0.010 | — |

| 0.100 | ±0.015 | ✔ |

| 0.145 | ±0.015 | ✔ |

| 0.175 | ±0.015 | ✔ |

| 0.210 | ±0.020 | ✔ |

| 0.300 | ±0.020 | ✔ |

| 0.400 | ±0.020 | ✔ |

| 0.550 | ±0.050 | ✔ |

| 0.550 | ±0.015 | ✔ |

| 0.700 | ±0.050 | ✔ |

| 1.100 | ±0.050 | ✔ |

| 1.100 | ±0.030 | ✔ |

| The thicknesses marked with "✔" are also available within 48–hour express service. | ||

| The thicknesses 0.070, 0.50 and 0.90 mm are sometimes available. If required, please send us a corresponding request. | ||

Optical Properties

- Abbe number: ve = 55

| Refractive index numbers | ||

|---|---|---|

| Designation

|

Wavelength (nm)

|

Refractive Index

|

ng |

436 |

1.5354 |

nF' |

480 |

1.5305 |

nF |

486 |

1.5300 |

ne |

546 |

1.5255 |

nd |

587.5 |

1.5231 |

nD |

589.3 |

1.5230 |

nC' |

644 |

1.5209 |

nC |

656 |

1.5204 |

Mechanical Properties

- Density: 2.51 g/cm3

- Young's modulus E: 72.9 kN/mm2

- Poisson's ratio μ: 0.208

- Torsion modulus G: 30.1 kN/mm2

- Knoop hardness HK100: 590

Thermal Properties

- Coefficient of mean linear thermal expansion

(static measurement): 7.2 × 10-6/K (20–300 °C)

- Viscosities:

- Working Point (104 dPa): 1051 °C

- Softening Point (107.6 dPa): 736 °C

- Annealing Point (1013 dPa): 557 °C

- Strain Point (1014.5 dPa): 529 °C

- Transformation temperature Tg: 557 °C

- Mean specific heat capacity (20–100 °C):

0.82 J/(g × K)

Chemical Capabilities

- Hydrolytic resistance according to DIN ISO 719:

- Hydrolytic Class HGB 1

- Equivalent of alkali (Na2O) per g of glass grains: 20 μg/g

- Acid resistance according to DIN 12 116:

- Acid Class S2

- Half surface weight loss after 6 h:

1.4 mg/dm2

- Alkali resistance according to DIN ISO 695:

- Alkali Class A2

- Surface weight loss after 3 h:

88 mg/dm2

Electrical Properties

| Dielectric Constant (permittivity) εr | ||||||

|---|---|---|---|---|---|---|

| Frequency in GHz | 0.001 |

1.0 |

2.0 |

5.0 |

24 |

77 |

6.7 |

6.4 |

6.4 |

6.3 |

6.3 |

6.1 |

|

| Loss Tangent tan(δ) x 10-4 | ||||||

|---|---|---|---|---|---|---|

| Frequency in GHz | 0.001 |

1.0 |

2.0 |

5.0 |

24 |

77 |

61 |

74 |

81 |

101 |

210 |

240 |

|

- Specific AC-Volume Resistivity ρD (Ω x cm):

- 1.6 × 108 (250 °C / 50 Hz)

- 3.5 × 106 (350 °C / 50 Hz)

Other materials from SCHOTT in our extensive delivery program are AF 32 eco, AS 87 eco, B 270 Superwite, BK7, and BOROFLOAT® 33. For further technical information, please feel free to contact us.

All data and specifications given are average guide values and are not guaranteed. Moreover, please consider the “Notes on Specifications”.

© 1994 – 2026 Präzisions Glas & Optik GmbH

Last update: December 17, 2025