Production and Glass Processing

Our Capabilities

Following, you will find a summary of the most established of our industrial glass processing techniques and our coating capabilities. These are only examples and a small fragment of our options. We are not limited to the processing techniques mentioned here. Please send us your request if you have further questions.

CNC-Precision Glass Cutting

• Economical cutting process

• Precision of up to +/-30 µm

• Clean cut edge without bevel

Glass Edging

(Grinding to diameter)

• Manufacturing of round or elliptical shapes

• Tight mechanical tolerances

• Effective and economical

• Ground edges

Lapping & Polishing

• Manufacturing of optically flat surfaces

• Polishing of colored glass filters

• Production of glass wafers

• Manufacturing of optical windows

• Manufacturing of optical substrates

• Polishing of Prisms

Glass Grinding

• Tight dimension tolerances

• High rectangular precision

• Preprocessing of flat surfaces

• Ground surfaces

• Clean and precise edges

Precision Beveling

• Functional or protective bevels

• Clean appearance of beveled parts

• Safer handling (no sharp glass edges)

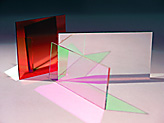

Optical Thin Film Coating

• Standard coatings

• Dielectric thin film coatings

• Metallic layers

• Transmissive coatings

• Reflection coatings

• Filter coatings

• Custom coatings

CNC-Shaping

• Manufacturing of complex shapes

• Tight mechanical tolerances

• High repetitive precision

Sandblasting &

Precision Drilling

• Full and partial glass matting

• Manufacturing of diffusers

• Sandblasting of glass surfaces

• Precision glass drilling

• Ultrasonic glass drilling

Other Glass

Processing Capabilities

• Water-jet cutting

• Precision Milling

• Precision sawing

• Thermal tempering

• Chemical tempering

• Optical cementing