Dielectric Mirrors for Visible Light

SHR Series

Special Properties

- Extremely high broadband reflectivity across the visible spectrum

- Optimized for a 45° angle of incidence

- Low absorption

- Metal-free, all-dielectric coating

- High thermal resistance

- Minimal losses

- Excellent infrared transmission

Typical Applications

- Broadband, high-reflection mirror for visible light

- Laser mirror

- Beam-separating and beam-combining optics for lighting systems and laser applications

- Injector mirror

- IR filter

- Metal-free mirror for use in strong magnetic fields

- Dichroic mirror (VIS/NIR+IR beam splitter)

Related Products

- SHD Series

(dielectric cold mirror) - SHP D Series

(dielectric mirror for polarized and unpolarized light) - SHP Series

(silver-coated mirror)

RFQ

![]() 48-hour Express Manufacturing

48-hour Express Manufacturing

Mirrors for maximum reflectivity

Dielectric mirrors are based on highly efficient interference-optical thin films. As front surface mirrors, they are vital components in a wide range of optical systems and are designed to reflect specific wavelengths of light or laser beams with the highest efficiency. They are especially useful in applications where metallic coatings do not provide sufficient reflectivity. A dielectric mirror is produced by a specialized vapor-deposition process. In contrast to a conventional metal-coated mirror, a dielectric mirror features multilayer coatings composed of non-metallic materials. Each layer is selected for its specific refractive index, forming a stack that is selectively reflective at desired wavelengths to achieve maximum performance.

High reflectivity across the entire VIS spectrum

All-dielectric mirrors generally exhibit angle-dependent reflectance and limited optical bandwidth, so they are typically optimized for single spectral lines or narrow wavelength ranges. Additionally, dielectric mirrors are often designed for only one or a small range of angles of incidence. While they offer much higher reflectivity than metal-coated mirrors, they typically have a narrower reflection bandwidth. To combine high and broadband reflectivity in a single optic, we developed our SHR mirror. The SHR mirror coating provides a reflection bandwidth that spans the entire visible spectrum, with excellent reflectivity at a 45° angle of incidence.

Dichroic characteristics

Another feature of our SHR mirror design is its ability to separate visible light from infrared radiation within a light beam. The SHR mirror offers high optical transmission for wavelengths beyond the visible spectrum, up to 2500 nm, enabling its use as an IR filter or dichroic beamsplitter. Some customers also use the SHR mirror as a beam-combining optic for lasers operating at different VIS and IR wavelengths.

Laser Mirror Application

The SHR mirror is suitable for reflecting laser beams at higher power levels due to its negligible absorption within its specified wavelength range. For information on supported laser types, beam power, and specific laser lines compatible with our dielectric SHR mirrors, please get in touch with our engineers. To assist us in evaluating your application, please provide details such as wavelength, beam diameter, required damage threshold, continuous laser power, and other relevant specifications.

Thermal Stability

Another significant advantage of our SHR is its excellent thermal stability. The mirror can operate at temperatures up to 350 °C, thanks to its high-quality, temperature-resistant borosilicate substrate. However, this assumes that the heating process is uniform and that temperature gradients across the mirror do not exceed its permissible physical limits.

Customized dielectric mirrors

We also offer custom dielectric mirror designs in production quantities, tailored to your specific requirements. Customized coatings for polarized light—beyond the standard SHR specifications—are available for sufficient order quantities. We also offer custom manufacturing of dielectric laser mirrors with increased optical flatness or ultra-high efficiency for particular laser lines, feasible on a per-coating-run basis. Polarization-optimized coatings are also feasible for larger orders. Please note, the polarization properties are not defined for our standard SHR mirrors; if polarization is critical to your application, please submit a detailed coating inquiry.

Request a quotation for custom-sized dielectric SHR mirrors by clicking the button below or selecting a material from the table.

Specifications

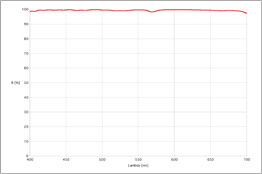

SHR reflection at 45° angle of incidence

Enlarge the curve to view details

Standard Mirror Thicknesses

| Thickness (mm) | Tolerance | |

|---|---|---|

| 1.10 | ± 0.10 | ✔ |

| 1.75 | ± 0.20 | ✔ |

| 3.30 | ± 0.20 | ✔ |

| Custom thickness is possible on demand. | ||

Reflection for unpolarized light at 45°

- Average reflectance (Ravg) > 99% at wavelengths from 425 to 680 nm at 45° incidence

- Average reflectance (Ravg) > 97% at wavelengths from 400 to 690 nm at 45° incidence

- Other wavelength ranges and incident angles per inquiry

- Customized mirror designs for polarized laser redirection applications are feasible on demand.

Substrates

- High-quality BOROFLOAT® 33 substrate (standard)

- Other substrates are possible upon request

Flatness

- Depends on the mirror thickness and material

- Precision up to λ/20 available upon request

Surface quality

- Typically better than 80–50 scratch & dig

(per MIL-0-13830A) - Higher SQ specification is possible on demand.

Mirror coating

- Dielectric layers only

- Low absorption

- Broadband thin-film coating system

Other properties

- Adherence to MIL-C-675 C (tape test)

- Abrasion-resistant to MIL-M-13508 C

- The damage threshold is unspecified for the SHR series. More details are available on demand.

Naming

- SHR highly reflective dielectric broadband mirror

Why No Shopping Cart

All our mirrors are manufactured to individual sizes to meet specific customer requirements. Often, we can produce and ship custom sizes faster than resellers can deliver catalog items with fixed dimensions, making a shopping cart unnecessary. If you are in the same time zone, you will typically receive a quote for your dielectric mirrors with individual dimensions within a few minutes. For further information on available options, please use our information request form.

All data and specifications given are average guide values and are not guaranteed. Moreover, please consider the “Notes on Specifications.”

© 1994–2025 Präzisions Glas & Optik GmbH

Last update: November 7, 2025