Cold Mirrors – Heat-transmitting mirror optics

SHD Series

Special Properties

- Highly efficient separation of heat and light

- Very high visible reflectivity

- High infrared transmission up to 2500 nm

- Excellent optical and imaging quality

- Temperature-resistant BOROFLOAT® substrate

- Designed for a 45° angle of incidence

- Multilayer mirror coating

- Vacuum deposited coating

- Thermal management in optical systems

Typical Applications

- Heat and light separation in lighting systems

- High-efficiency mirrors

- IR-transmitting mirror optics in optical systems

- Sensor technology

- Dichroic beamsplitter

- Projection systems

- Mirrors for medical lighting devices

- Cold light sources

- Laser mirrors

- Heat filters for fiber optic systems

- Low-cost 45° laser mirrors

- Laser diode applications

- Heat management in sensitive optical devices

- Laser beam combiners

- Infrared filters (NIR-IR)

- VIS blocking filters

Similar Mirror Types

- SIR Series

(hot mirror) - SHR Series

(dielectric optical mirror) - SHP-D Series

(broadband mirrors optimized for polarized light reflection) - SUV Series

(UV cold mirror)

Cold mirrors play a critical role in a wide range of applications requiring precise heat/light management. In lighting technology, heat-transmitting cold mirrors protect sensitive objects from potential heat damage by allowing infrared energy to pass through the mirror while reflecting the cold visible light. In fiber optic systems, SHD can prevent fiber destruction when a light source with high thermal energy in its spectrum is to be focused into a fiber.

We have designed our dichroic SHD cold mirrors to reflect at an angle of 45° (90° deflection) and transmit infrared wavlengths at 0° relative to the incident beam path. The mirrors provide very high optical reflectivity for visible light while transmitting more than 90% (average) of the infrared wavelengths up to 2500 nm.

In addition to its primary use as a cold mirror, the SHD can be used to combine visible with infrared light or laser beams. It also functions as a highly efficient and cost-effective laser mirror in the visible. Its dielectric mirror construction ensures permanent resistance to thermal stress and moisture. Selected BOROFLOAT® glass substrates allow the SHD cold mirrors to operate at elevated temperatures.

Furthermore, we offer the manufacturing of customized cold mirror optics. We can modify the layer design in terms of reflection wavelength, angle of incidence, cut-on and cut-off wavelengths, damage threshold, and spectral operating range of the reflective coatings on a batch basis. If you need assistance with your individual cold mirror design, please use our inquiry form to let us know your detailed requirements.

Please click below or select an option from the table to receive a quotation for our standard SHD cold mirrors with custom dimensions.

If you are interested in other mirror coatings or filters that control thermal energy or infrared wavelengths, please consider visiting our SIR mirrors and KG heat-absorbing filter spec sheets.

Specifications

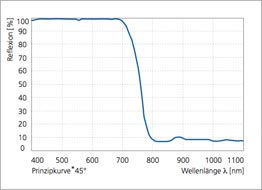

Reflection performance

of the SHD cold mirrors

Enlarge the curve to show the SHD reflection

Stock Thicknesses

Thickness (mm) |

Tolerance |

|

|---|---|---|

| 1.10 | ±0.10 | ✔ |

| 1.75 | ±0.20 | ✔ |

| 3.30 | ±0.20 | ✔ |

| Custom thicknesses are available on request. | ||

Optical Reflection and Transmission (AOI 45°)

- Reflectance (R) > 99% for single wavelengths

- Average reflectance (Ravg) > 97% at 400–690 nm

- Average transmission (Tavg) > 90% at 800–2500 nm

- Other wavelength ranges and different incidence angles per inquiry

Construction

- Metal-free, 100% dielectric layers

Substrates

- Temperature-resistant BOROFLOAT®

- Other substrates are possible on demand

Flatness

- Depending on the substrate

Surface Quality

- Typical 80-50 scratch & dig (MIL-0-13830A)

- Other on request

Standard Thicknesses

- 1.10 mm | 1.75 mm | 3.30 mm

Adherence and Abrasion Resistance

- Adherence according to MIL-C-675 C (tape test)

- Abrasion-resistant according to MIL-M-13508 C

Note: If you are searching for optics with the inverse function principle of the dichroic SHD cold mirrors that reflect heat and let the visible spectrum pass, please refer to our SIR heat-reflecting filters (hot mirrors).

All data and specifications given are average guide values and are not guaranteed. Moreover, please consider the “Notes on Specifications”.

© 1994 – 2026 Präzisions Glas & Optik GmbH

Last update: February 18, 2026