ITO Coatings – Transparent, Conductive Glass

CEC Series

Special Properties

- Conductive coating with excellent light transmission

- Sputter coated ITO on high-quality glass substrates

- Low micro-roughness

- SiO2 passivation layer between the substrate and the ITO film (CEC-S and CEC-P series only)

- High reflection for infrared light

- High uniformity of surface resistance

- Superb abrasion resistance and adhesion of the coating

- Patterning can be done by laser or by etching

- Sheet resistivities range from 3.5 Ω/□ to 1 kΩ/□

Typical Applications

- LCD and OLED display technology

- Touch screens and touch-sensitive display technology

- Microscope slides for medical science and research

- Anodes for OLEDs (organic light-emitting diodes)

- MEMS (Micro-Electro-Mechanical Systems)

- EMF, EMI, EMC, RFI, and RF shielding

- Transparent electrodes and capacitors

- Temperature-controlled microscope stages

- Heated cover glasses for scientific and medical research

- Invisible conductor tracks

- Microscope heating stages

- Ultra-flat antennas for mobile communication devices

- Conductive object carriers

- Space optics

- Organic solar cells

- Mirrors and reflectors for the infrared range

- Heated windows with defrost function

Related topics and websites

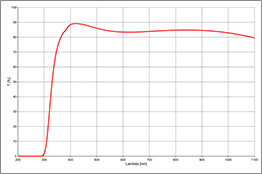

- Transmission curves of all ITO coatings

- FAQ: Transparent, Conductive ITO Coatings

(Frequently Asked Questions) - CUT (copper adhesive tape for contacting ITO)

RFQ

![]() 48-hour express service

48-hour express service

Our ITO coatings are the ideal solution when glass with an electrically conductive surface and high optical transmission is required. We achieve these properties by sputter deposition of a thin indium tin oxide film onto high-quality substrates. ITO is used in almost all LCD and touch screens and often forms the anode in OLED displays. Indium tin oxide is ideal for manufacturing transparent electrodes, integrated invisible flat antennas in mobile devices, antistatic glass, heating, antifog, and de-icing windows, organic solar cells, and many other applications.

Indium tin oxide coatings with low electrical resistance exhibit high reflectivity in the infrared range, allowing them to be used as IR mirrors or filters while remaining transparent in the visible spectrum. Furthermore, transparent conductive coatings can shield electromagnetic fields. Many of our CEC materials are ideal for the production of EM shielding glasses that can attenuate electromagnetic radio waves.

We manufacture microscope slides and cover glasses based on the substrate materials listed in the table on this page in all standard laboratory formats for science and research. Regardless of whether you need small parts for microscopy or large sheets for photovoltaic research, many sizes are possible. Our ITO-coated materials are also an excellent solution for micro-structuring or patterning applications, which can be done with a laser or by etching. We are pleased to provide typical etching recommendations on request.

Our CEC-S and CEC-P series feature a SiO₂ passivation layer. This quartz barrier is only a few nanometers thick. It is located between the substrate and the TCO (transparent conductive oxide) coating, so the conductive layer remains on top and is only in direct contact with the high-purity quartz layer. This prevents direct contact with the soda-lime glass. This so-called passivation prevents the otherwise occurring leaching of alkali oxides from a soda-lime substrate into the liquid crystals of a display, which is essential to the longevity of LCDs and a significant benefit for most electronics applications. The thin SiO₂ barrier improves the performance of the products nearly without increasing cost, as the deposition of this layer is efficiently integrated into the deposition process. The protection against alkali oxides achieved with the SiO2 passivation layer is superior to any other technology.

In addition to the popular S-series and P-series coated on selected HQ float glass, we produce many other conductive coatings based on more exotic substrates. ITO-coated optical grade quartz (CEC-Q), borosilicate glass (CEC-B), alkali-free 1737F (CEC-A), EAGLE2000 (CEC-E), thin glass (CEC-T), and our double-sided coated CEC-SD are part of our extensive production program. Most of the coatings listed in the table are typically available from stock. Furthermore, we offer solutions with customized layer thicknesses, on special glasses, or with an electrical conductivity not listed in the table. Moreover, an additional anti-reflective coating can be applied to the rear side in a separate production batch. Customization for your specific requirements is available upon request for sufficiently large quantities. Please use our inquiry form to send us your exact specifications, and we will be happy to provide a quote.

Customized Dimensions

Since almost every application requires a specific part size, we have deliberately not limited our product range to a few fixed sizes. Most of our materials listed in the table can be quickly produced to your size specification, even for larger quantities. We typically process most dimensions in less than a week, so custom sizes can often ship as quickly as standard stock items. Delivery for custom sizes can be even faster with our 48-hour express option. Whether you need small parts for organic LED displays (OLEDs), larger sizes for solar cells, or standard microscope slide dimensions, all of these are possible.

Please click the button below or select the desired thickness in the table to request a quote for our ITO coatings with custom dimensions.

![]() Available with 48-hour express service

Available with 48-hour express service

Visit our ITO FAQ web page for more details about our transparent conductive indium tin oxide coatings and deposition services.

Specifications

View all ITO transmission curves

Display the spectral curves of all ITO products

ITO Coatings | Stock Materials

Please click a thickness to begin a request:| Sheet Resistance Rsq | ||||

|---|---|---|---|---|

| Product code |

specified (Ω/□) |

typical (Ω/□) |

typical film THK (nm) |

available thicknesses (mm) |

| CEC004S | 4±1 |

3.5 | n/a | 1.1 |

| CEC005S | ≤ 5 |

4.5 | 310 | 1.1 |

| CEC007S | ≤ 7 |

6 | 260 | 1.1 |

| CEC010S | ≤ 10 |

8.5 | 180 | 0.7 | 1.1 |

| CEC017S | ≤ 17 |

14 | 110 | 1.1 |

| CEC020S | ≤ 20 |

15 | 100 | 0.7 | 1.1 |

| CEC030S | ≤ 30 |

24 | 65 | 1.1 |

| CEC040S | ≤ 40 |

30 | 50 | 1.1 |

| CEC050S | ≤ 50 |

40 | 40 | 1.1 |

| CEC100S | 100±20 |

95 | 23 | 0.55 | 0.7 | 1.1 |

| CEC120S | ≤ 120 |

100 | 21 | 1.1 |

| CEC300S | 300±50 |

300±50 | 20 | 1.8 |

| CEC500S | 500±160 |

500±160 | 15 | 0.3 | 0.4 | 0.7 | 1.1 | 1.8 |

| CEC050SD | 50±10 |

50±10 | 34 | 0.55 |

| CEC005P | ≤ 5 |

4.5 | 310 | 0.5 | 0.7 |

| CEC007P | ≤ 7 |

6 | 260 | 0.4 | 0.7 |

| CEC010P | ≤ 10 |

8.5 | 180 | 0.4 | 1.1 |

| CEC015P | ≤ 15 | 12.5 | 120 | 0.4 |

| CEC020P | ≤ 20 |

15 | 100 | 1.1 |

| CEC030P | ≤ 30 |

24 | 65 | 0.4 | 1.1 |

| CEC050P | ≤ 50 |

40 | 40 | 1.1 |

| CEC060P | ≤ 60 | 50 | 33 | 0.55 |

| CEC080P | ≤ 80 |

65 | 25 | 0.4 |

| CEC010A | 10±2.5 | 10±2.5 | n/a | 1.1 |

| CEC020A | 20±5 | 20±5 | n/a | 0.7 | 1.1 |

| CEC025A | 25±6 | 25±6 | n/a | 0.7 | 1.1 |

| CEC007B | 7±2 |

7±2 | n/a | 1.1 |

| CEC010B | 10±3 |

10±3 | n/a | 1.1 | 1.75 | 2.0 | 3.3 | 5.0 |

| CEC015B | 15±5 |

15±5 | n/a | 3.3 |

| CEC020B | 20±6 |

20±6 | n/a | 0.7 | 1.1 | 3.3 | 5.0 |

| CEC010E | 10±3 | 10±3 | n/a | 1.1 |

| CEC020E | 20±5 |

20±5 | n/a | 1.1 |

| CEC005F | 5±1 | 5±1 | n/a | 1.0 |

| CEC007F | 7±2 | 7±2 | n/a | 1.0 |

| CEC010F | 10±3 | 10±3 | n/a | 1.0 | 2.0 | 3.0 |

| CEC015F | 15±4.5 |

15±4.5 | n/a | 1.0 | 3.0 |

| CEC020F | 20±6 |

20±6 | n/a | 1.0 |

| CEC050F | 50±12.5 |

50±12.5 | n/a | 1.0 |

| CEC100F | 100±25 |

100±25 | n/a | 0.7 | 1.0 |

| CEC020Q | 20±6 |

20±6 | n/a | 1.0 |

| CEC020T | 20±5 |

20±5 | n/a | 0.175 | 0.3 |

| Customization

A custom film thickness, glass material, thickness (≥ 0.175 mm), conductivity (3.5 Ω - 1 kΩ/□), or backside anti-reflection coating is possible per batch upon request. Don't hesitate to contact us for more details. Film thickness We control the film thicknesses of all CEC-S, CEC-P, and CEC-SD coatings with an in-situ process. All other, more exotic substrates are deposited in a smaller chamber, so the exact layer thickness is not a process-controlled parameter for these materials. We only control the surface resistivity and the transmissivity of these coatings. These coatings are therefore marked “n/a” in the corresponding column of the table. Contacting ITO For contacting, you can use spring contacts, suitable silver paint, or our copper tape. |

||||

- CEC-S & CEC-SD: selected HQ float glass

- CEC-P: polished HQ float glass

- CEC-A: 1737F, near-zero alkali aluminosilicate glass

- CEC-B: Borosilicate glass

- CEC-E: EAGLE2000, akali-free boro-aluminosilicate

- CEC-F: selected float glass

- CEC-Q: Polished optics-grade quartz glass

- CEC-T: D263 Thin-glass

- Other substrates are available upon request.

- CEC-S and CEC-P:

- Indium tin oxide coating on one side

- SiO₂ passivation layer between ITO and substrate:

— quartz thickness at Rsq ≤ 120 Ω/□ : ∼ 25 nm

— quartz thickness at Rsq = 500 Ω/□ : ∼ 65 nm

- CEC-A, CEC-B, CEC-E, CEC-F, CEC-Q, and CEC-T:

- Indium tin oxide coating on both sides

- No SiO₂ passivation layers

- CEC-SD:

- Indium tin oxide coating on one side

- One SiO₂ passivation layer per side:

SiO₂ layer thickness: ∼ 20 nm

- The total refractive index of our ITO coatings is unspecified.

- The refractive index of the glasses is listed in the respective material datasheets (see links above).

- The refractive index of transparent indium tin oxide films is around 1.95 for visible wavelengths.

- Depending on the substrate material

- Better than 80-50 scratch and dig (MIL-0-13830A)

- Others upon request

- According to MIL-C-675 A (4.6.11, Rubber test)

- According to MIL-M-13508 (4.4.6, Tesa test)

- Copper tape

- Spring contacts

- Silver paint

Please use our information request form for more details about our indium tin oxide coatings.

All data and properties given are average guide values and are not guaranteed. Please also consider the Notes on Specifications.

© 1994 – 2026 Präzisions Glas & Optik GmbH

Last update: December 17, 2025