Protected Aluminium Mirrors

AL+SiO2 mirror coatings for ultraviolet light

SEA-UV Series

Special Properties

- High reflection from about 250 nm to 10 µm

- Excellent optical characteristics

- Metallic coating

- Aluminium coating protected by a thin quartz layer

(Al+SiO2) - Selected HQ substrate material

Typical Applications

- Mirrors for ultraviolet wavelengths

- UV laser applications

- UV-VIS-IR mirrors

- Mirrors for medical devices

- UV-curing systems

- Alternative to silver or gold mirrors

- UV-sensor technology

- Broadband laser optics

- UV mirrors for disinfection systems

Related mirror types

- SEA-VIS Series

(Enhanced aluminum mirrors, VIS) - SEA-NIR Series

(Enhanced aluminum mirrors, NIR-IR) - SHP Series

(High-reflection Silver FSM)

Get a price quote

![]() 48-hour express manufacturing

48-hour express manufacturing

Our protected aluminium mirrors from the SEA-UV series offer high reflectivity for ultraviolet wavelengths. They are based on an aluminium coating that is protected by a thin quartz layer.

Bare aluminium metal coatings quickly oxidize when exposed to oxygen. Furthermore, such optics are extremely sensitive to scratching. The quartz coating on top of the metallic layer of our protected aluminium mirrors prevents oxidization. Moreover, it makes the SEA-UV mirrors more scratch-resistant and durable than the soft and sensitive bare-aluminium mirrors. Still, protected aluminium mirror coatings are more delicate and susceptible to scratching than other mirrors, which can have a significantly thicker protective coating because they don't need to reflect ultraviolet light. Hence, in general, protected aluminium mirrors should not be used in harsh environments or when exposed to mechanical abrasion.

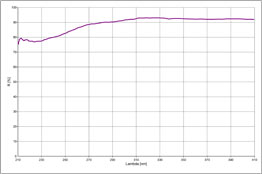

Because of the metallic layer, the reflection of our SEA-UV mirror coatings is far less angle-dependent than that of a dielectric coating. The optics feature a high and broadband reflectivity for the ultraviolet-to-infrared wavelength range. Only close to around 700–870 nm there is a moderate reflection drop down to slightly below 80%. Above this wavelength spectrum, the reflectivity of the mirror stays continuously high, up to 10 µm. At moderate laser power, SEA UV mirrors can even be used as laser mirror optics for multiple wavelengths in the UV, visible, and infrared ranges simultaneously. In some applications, the SEA-UV mirrors can replace gold or silver mirrors.

We can modify and increase the reflectivity of the coatings for a specific wavelength or a particular reflection range by adding thin dielectric layers. Please consider using our custom coating form to conveniently request a quotation for mirror optics based on your specific requirements. Please contact us if you need additional information or technical support.

To quickly receive a quote for our SEA-UV-protected aluminium front surface mirrors with the size you need, please click the button below or select a thickness from the table:

Specifications

SEA-UV Reflectance

Enlarge the reflectance curve to show details

Standard Thicknesses

(Please click on the desired thickness for a price quote.)Thickness (mm) |

Tolerance |

|

|---|---|---|

| 1.00 | ±0.10 | ✔ |

| 2.00 | ±0.20 | ✔ |

| SEA-UV with custom thickness. | ||

| The thicknesses marked with "✔" are also available within our 48–hour express option. | ||

Optical Reflection (45° incidence angle)

- Average reflectance (Ravg) > 85% at 280–700 nm

- Absolute Reflectance (Rabs) >/= 90% at 300–400 nm

Coating construction

- Al + SiO2

Substrate Material

- Selected Float

- Other substrates are available on request

Flatness

- Depending on the substrate material and thickness

Surface Quality

- Typ. 80-50 scratch & dig (MIL-0-13830A)

MIL-Standards

- Adherence according to MIL-C-675 C (tape test)

- Abrasion-resistant according to MIL-M-13508 C

If you need mirror optics solely for the visible wavelength range, please look at our SEA-VIS mirror, which is enhanced for the visible range. Moreover, please visit our SHP silver metal mirrors spec sheet. For the near-infrared wavelength spectrum, our SEA-NIR mirrors might be an option for you.

© 1994–2026 Präzisions Glas & Optik GmbH

Last update: October 31, 2025