Enhanced Aluminum Mirrors

Al front surface mirror optics with dielectric overcoatings

SEA-VIS & SEA-NIR Series

Special Properties

- Aluminum mirror coating with additional dielectric coatings for increased reflection

- Excellent imaging quality with no ghosting

- Broad spectral performance (visible or near-infrared)

- High durability and abrasion resistance

- Also possible with large dimensions

- Efficient near-infrared reflection (SEA-NIR only)

- Economical alternative to gold-coated mirrors

- Metallic + dielectric coating system

- Cost-effective optical solution

Typical Applications

- Mirrors for optical systems

- Laser mirrors for up to medium-power lasers

- Laboratory and scientific instruments

- Sensor technology and machine vision

- Industrial automation and inspection systems

- Mirror optics for imaging systems

- Medical instruments and devices for optometry

- Optics for office machines, episcopes, copiers, or optical projectors

- Photonics and optical communications

- Replacements for silver or gold mirrors

- Laser barcode scanners and projection systems

Related Metallic Mirror Types

- SEA-UV Series

(Protected aluminum mirrors UV-IR) - SHP Series

(Silver front surface mirrors)

Our SEA product family encompasses a range of high-performance broadband front surface mirrors designed to meet diverse optical requirements across visible and near-infrared spectra. Both SEA-VIS and SEA-NIR mirrors utilize an aluminum coating, which is enhanced by dielectric overcoatings. These layers significantly improve reflectivity and protect the aluminum coating from oxidation, scratches, and environmental damage. Compared to the standard soft protected aluminum or silver mirror coatings, lacking a robust, protective multilayer coating system, both enhanced aluminum mirror series substantially provide better scratch, moisture, and abrasion resistance.

Low-Cost Mirror Optics for the Visible Range

SEA-VIS enhanced aluminum mirrors are versatile, cost-effective optics optimized for the visible spectrum. They are ideal for projects requiring high reflectivity, precise imaging, surface flatness, and mechanical stability. Due to its comparatively economical price, it is the ideal front surface mirror for large-volume projects and whenever a large mirror size is required.

SEA-VIS enhanced aluminum mirrors are versatile, cost-effective optics optimized for the visible spectrum. They are ideal for projects requiring high reflectivity, precise imaging, surface flatness, and mechanical stability. Due to its comparatively economical price, it is the ideal front surface mirror for large-volume projects and whenever a large mirror size is required.

Highly Reflective in the Near Infrared Spectrum

SEA-NIR mirror optics offer the same high quality as the SEA-VIS but are enhanced for the near-infrared wavelength region, where most standard aluminum mirrors experience a significant reflectivity drop. In many applications, the mirrors could even replace gold mirror optics, resulting in significant cost savings.

SEA-NIR mirror optics offer the same high quality as the SEA-VIS but are enhanced for the near-infrared wavelength region, where most standard aluminum mirrors experience a significant reflectivity drop. In many applications, the mirrors could even replace gold mirror optics, resulting in significant cost savings.

Premium-Quality Substrates, Clearer Images

The coatings of all SEA optics are coated on high-quality glass substrates. Applying the mirror coating directly to the substrate’s surface ensures exceptional image quality. This front surface mirror design eliminates the double images commonly seen with conventional rear-coated mirrors and keeps energy losses low.

SEA Mirrors in Laser Applications

All SEA front surface mirrors are suitable for use with up to medium-power lasers within their designed reflection wavelength range. Please contact us to verify compatibility with your laser beam and let us know the laser wavelength, beam diameter, the required damage threshold, and laser power or energy you want to reflect.

Any Size, Any Shape, and Custom Coatings

We don’t limit you to a few standard sizes or shapes. You can specify any dimensions or shape to precisely meet your requirements. Additionally, we can tailor the center wavelength of reflectivity enhancement in custom coating runs. Use our inquiry form to provide your custom enhanced aluminum front surface mirror requirements.

To request mirrors with individual dimensions, please click on one of the buttons below or select a material from the table.

Frequently Asked Questions (FAQ)

For more detailed information about our SEA-VIS and SEA-NIR mirrors, please visit our Frequently Asked Questions page.

Specifications

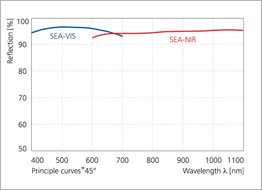

Reflection curves

Show details

Standard thicknesses

| Thickness (mm) | Tolerance | |

|---|---|---|

SEA-VIS Enhanced Aluminum Mirror Optimized for visible light |

||

| 0.55 | ± 0.05 | ✔ |

| 1.00 | ± 0.10 | ✔ |

| 1.10 | ± 0.10 | ✔ |

| 2.00 | ± 0.20 | ✔ |

| 3.00 | ± 0.20 | ✔ |

| 4.00 | ± 0.20 | ✔ |

| 5.00 | ± 0.20 | ✔ |

| 6.00 | ± 0.20 | ✔ |

| SEA-VIS with custom thickness or tolerance | ||

SEA-NIR Enhanced Aluminum Mirror Optimized for near-infrared light |

||

| 2.00 | ± 0.20 | ✔ |

| 3.00 | ± 0.20 | ✔ |

| SEA-NIR with custom thickness or tolerance | ||

| Mirror thicknesses marked with ✔ qualify for our 48-hour express manufacturing service. | ||

Reflectance

SEA-VIS

- Reflectance (R) > 94% at 550 nm, angle of incidence (AOI) 45°

- Average reflectance (Ravg) > 93% over 450–650 nm,

AOI 15–45° - Average reflectance (Ravg) > 92% at 550 nm for

S- and P-polarized light, AOI 15–45° - Center wavelength shift possible on request

- Average reflectance (Ravg) > 93.5% over

700–1200 nm, AOI 45° - Center wavelength shift possible on request

- Standard substrate: selected float glass

- Other substrates are available on request

- Aluminum coating with non-metallic overcoatings

- Flatness depends on substrate, thickness and size

- Up to λ/10 available upon request

- 80-50 scratch and dig or better

- Coating adherence according to MIL-C-675C

(tape test) - Abrasion resistance per MIL-M-13508C

- Rectangular mirrors up to approx. 800 mm x 1250 mm

- Circular mirrors up to approx. 600 mm diameter

Mirror Optics for the UV Range

For ultraviolet applications, please refer to the SEA-UV mirror. This protected aluminum mirror features a thin SiO₂ (quartz) protective layer over the aluminum coating instead of the multilayer overcoating used in enhanced aluminum mirrors, enabling UV and broadband UV–to–IR performance (see separate data sheet).

All data and specs given are average guide values and are not guaranteed. Moreover, please consider the Notes on Specifications.

© 1994–2026 Präzisions Glas & Optik GmbH

Last update: December 17, 2025