Home / Products / Thin Film Coatings / Plate Beam Splitters

Optical Beam Splitters

45° Splitter Mirrors, DST series

Special Properties

- Neutral division of light beams, lasers, and images

- Anti-reflection-coated back side

- Effective suppression of double images

- Low-absorption dielectric layer system

- Designed for unpolarized light

- 100% metal-free

- Large dimensions possible (DST500)

Typical Applications

Related Products

- Optical beam splitter optics for light and lasers

- Divider mirrors for reference measurement systems

- Partially transparent splitters for interferometers

- Measurement and sensor technology

- Applications in photonics and photon research

- Image processing in automation technology

- Laser combination mirror

- Plate beam splitters in optical benches

- Fiber optic applications

- Optical data-transmission technology

- LED measurement technology

- SIR Series

(IR-reflecting dichroic beamsplitters)- SHD Series

(IR-transmitting dichroic beamsplitters)- ND filters

(Attenuation filters made from SCHOTT NG materials)- TDS Spy-Mirrors

(Partially transparent “one-way mirror”)

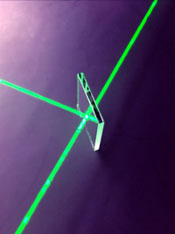

Beam Splitters are Core Elements in Optics

Beam splitters are important components in a wide range of optical systems. They are also known as dividing mirrors or partially transparent mirrors, as they split incident light into two components that are deflected in different directions. Due to their optical properties, beam splitter optics are used in numerous industries such as telecommunications, spectroscopy, microscopy, laser technology, and also in research.

Precise Light Division with Minimal Loss

Our DST beam splitters divide incident light beams into transmission and reflection components in a defined ratio. A light beam, laser, or image is partially reflected by a beam splitter as if by an optical mirror and partially transmitted as if through an optical window. The input side of the beam splitter plates is coated with a dielectric coating, which determines the division ratio of reflection to transmission. On the rear side, the DST features a broadband anti-reflection coating, which virtually eliminates secondary reflections, ghost images, and phantom laser beams. Hence, reflection losses and blurring caused by image overlaps due to disruptive reflections from the rear of the glass substrate do not occur. We use high-quality, iron-reduced glass with low absorption in display quality as the substrate material for our beam splitters.

Color-Neutral and Highly Efficient

Unlike dichroic beam splitters, which separate different optical spectral ranges from each other, our DST divides the visible spectrum in a very color-neutral manner. A non-metallic design ensures good durability and abrasion resistance. Furthermore, the DST beam splitter coatings exhibit very low optical absorption in the nominal wavelength range. Unlike metallic beam splitters, therefore, very little energy is lost. Our beam splitter plates are often found in optical benches and reference measurement systems to split lasers with low to medium laser power into multiple beams with nearly no loss.

Optimized for Unpolarized Light

All DST beam splitters are generally designed for light sources without defined polarization, i.e., for unpolarized light. When using our DST with polarized light or with a polarized laser, the splitting ratios may therefore deviate from the specifications given, which are only specified in this data sheet for random polarization. They are therefore not defined in terms of polarization behavior or polarization effects. However, the use with polarized light sources is by no means excluded. Often, the desired division can be achieved by selecting a higher or lower existing splitting ratio, thereby drastically reducing costs compared to a customer-specific coating batch.

Customized and Polarizing Beam Splitters

If you require beam splitters for polarized light or for a polarized laser, contact us with details of the wavelength, splitting ratio, laser power, and all other relevant specifications. For special requirements regarding polarization properties, we can also offer polarization-optimized, customized splitter optics for sufficiently large production quantities. In addition to our standard DST300, DST500, and DST700 series, optical beam splitters with other splitting ratios are also available on a batch basis. Polarizing beam splitter cubes, beam splitter pentaprisms, NIR dividing mirrors, and high-performance beam splitters are also possible. Components such as polarizing or non-polarizing cube beam splitters and special beam-splitting prisms are always custom-made and are therefore not listed individually as products on our website. To inquire about such optical components or to request technical support and further information, please use our inquiry form.

Custom Dimensions, Lightning-Fast Turnaround

Our company specializes in manufacturing any optic with customer-specific dimensions at extremely short notice. As a result, we can often deliver customized beam splitters just as quickly or even faster than a finished product can be shipped from stock. This even applies to large production quantities! As a rule, you will receive our quote within a few minutes, provided you are in our time zone and there are no queries.

To conveniently request one of our DST beam splitters with custom dimensions using our inquiry form, click the button below:

Specifications

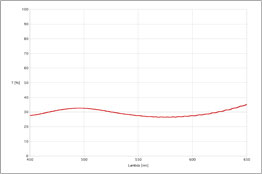

DST300

Enlarged view of the DST300 curve

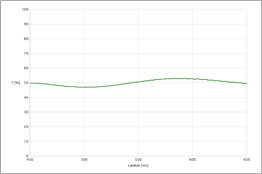

DST500

Enlarged view of the DST500 curve

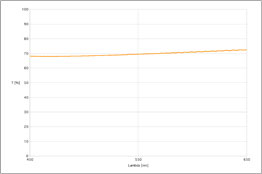

DST700

Enlarged view of the DST700 curveStandard Thicknesses

To inquire, please click on a thickness:

| Thickness (mm) | Tolerance | |

|---|---|---|

| DST300 beamsplitters R : T = 70 : 30 |

||

| 1.00 | ±0.10 | ✔ |

| DST500 beamsplitters R : T = 50 : 50 |

||

| 1.00 | ±0.10 | ✔ |

| DST500T beamsplitters R : T = 50 : 50 |

||

| 3.30 | ±0.20 | - |

| DST700 beamsplitters R : T = 30 : 70 |

||

| 1.00 | ±0.10 | ✔ |

| Other thicknesses per inquiry. | ||

| All DST beamsplitters have an AR coating on the back. | ||

| Thicknesses marked with ✔ are also available in our 48-hour express service. | ||

Dimensions

- Up to approx. 630 mm × 810 mm (only for flat beamsplitter plates, not possible for prisms, NIR beamsplitters, polarizing optics, or beamsplitter cubes.)

Splitting Ratios at 45° Angle of Incidence

(All ratio data refer to random polarization.)

DST300

- R/T = 70/30 (± 10%) for 450–650 nm

DST500

- R/T = 50/50 (± 6%) for 450–650 nm,

R/T = 50/50 (± 10%) for 430–685 nm

DST500T

- R/T = 50/50 (± 10%) for 450–650 nm

DST700

- R/T = 30/70 (± 8%) for 450–650 nm,

R/T = 30/70 (± 10%) for 400–700 nm

Other division ratios are available on demand.

Substrate Materials

Flatness

- Selected float glass

- BF33 Borosilicate glass (DST500T only)

- Other substrate materials per inquiry

Surface Quality

- Depends on material and thickness

Other Specifications

- Better than 80-50 scratch & dig (MIL-0-13830A)

- Other qualities per inquiry

- Adherence according to MIL-C-675 C (tape test)

- Abrasion resistance according to MIL-M-13508 C

If you require further information or cannot find the divider mirror you are looking for on our website, please send us your inquiry.

All details and specifications given are mean reference values and are not guaranteed. Please also consider our “Notes on Technical Specifications”.

© 1994–2026 Präzisions Glas & Optik GmbH

Last update: December 17, 2025