Fused Quartz Glass for Sight Glasses

If you need optical quality, please visit the Fused Silica data sheet.

Special Properties

- Heat-resistant up to over 1000 °C (short-term)

- High thermal shock resistance

- Excellent chemical durability

- Low coefficient of expansion

- UV transparent

- Uniform infrared transmission up to 2600 nm

- Non-crystalline silica glass

- More economical than optical grade fused silica

Typical Applications

- Heat-resistant sight glasses

- Front cover glass for UV lamps

- Flame monitoring

- Material for industrial quartz components

- UV LED covers

- Protective windows

- Medical UV disinfection systems

- High-temperature viewing ports

- UV drying and curing systems

- Housings for ultraviolet light sources

- Quartz parts for the chemical industry

Related Glass Types

- Quartz glass for optics (fused silica)

- Glass wafers

- BOROFLOAT® 33 from SCHOTT (borosilicate glass)

Discover our Quartz Glass FAQ page to help you choose the right type of quartz material for your application.

Your best choice for high-temperature sight glass applications

Fused quartz is a non-crystalline amorphous glass made by flame-melting natural silica crystals with an SiO₂ content of 99.98%. Any quartz glass material contains primarily silicon and oxygen. This is also the case with fused quartz. However, it does not provide the excellent purity and low inclusion content of the much more expensive optical-grade fused silica materials. Since optical purity is irrelevant for the front glasses of UV lamps, high-temperature viewing ports, heat-resistant inspection windows, or other industrial use cases, fused quartz glass is the ideal and most economical material choice for such applications.

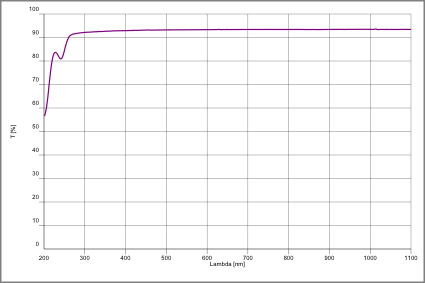

The low expansion, high thermal resistance, and excellent chemical properties of fused quartz are comparable to those of optical-grade silicon dioxide materials. Furthermore, the high transmission of ultraviolet light down to a wavelength of about 200 nm is essential for UV curing or disinfection systems. Moreover, fused quartz has a high, uniform transmission up to 2600 nm enabling many high-temperature applications in the infrared. It also offers high resistivity and outstanding insulation properties.

Our fused quartz glass is made transparent by a low-cost polishing process. The thickness tolerance and parallelism achieved by this polishing process are relatively coarse, and flatness and surface quality are not on a level required for optics. However, in most cases where these sight glass materials are used, this is completely irrelevant and helps to keep the cost low. Nevertheless, the glass is clear, and a direct, straight view through the glass shows virtually no perceptible distortions or inhomogeneities.

Please click the button below to request a quote for your sight-glass-grade fused quartz window:

![]() 48-hour manufacturing and delivery

48-hour manufacturing and delivery

For some thicknesses, we offer 48-hour express fabrication. Please refer to the table for glass thicknesses possible for this option.

Specifications

Transmission at 3 mm in the UV-NIR range

Glass Thicknesses

Fused quartz glass is not usually available as a blank sheet material, so there are no standard thicknesses. However, we continuously produce and polish several common thicknesses to offer our customers the best possible availability. Please refer to the table below for the most common fused quartz thicknesses polished for sight glass applications. Even our 48-hour delivery option is possible for these materials if needed.

Please select glass thickness to start an inquiry:

| Thickness (mm) |

Tolerance | |

|---|---|---|

| 1.0 | ±0.2 | ✔ |

| 1.1 | ±0.2 | ✔ |

| 2.0 | ±0.3 | ✔ |

| 3.0 | ±0.3 | ✔ |

| 5.0 | ±0.5 | ✔ |

| Custom thicknesses are possible on request. | ||

| For thicknesses marked with ✔, our optional 48-hour express fabrication is possible. | ||

Optical Properties

- UV-Transmission:

Approximately 90% at 260 nm (at 3 mm thickness) - Refractive Index: nd = 1.459

Mechanical Properties

- Density: 2.20 g/cm3

- Young's modulus: ca. 7.2 × 1010

- Poisson's number: 0.17

Thermal Properties

- Coefficient of thermal expansion:

Approx. 0.55 × 10-6/K (25–300 °C) - Maximum operating temperature:

- Short-term use: up to approximately 1100 °C

- Long-term use: up to about 850 °C

- Thermal conductivity: approx. 1.4 W/K m

Electrical Properties

- Dielectric constant εr: 3.75 (1 MHz)

- Loss factor: < 2 × 10-4 (20 °C ; 1 MHz)

- Specific resistivity: 7.0 × 109 Ω x cm (350 °C)

- Insulation capacity: 5 × 10-7 V/m

If you are searching for higher-grade quartz glass suitable for optical or semiconductor applications, please refer to our synthetic fused silica data sheet for detailed information.

All data and specifications given are average guide values and are not guaranteed. Moreover, please consider the “Notes on Specifications”.

© 1994 – 2026 Präzisions Glas & Optik GmbH

Last update: February 11, 2026