High Reflection Mirrors for polarized and unpolarized light

SHP-D Series

Special Properties

- 100% dielectric high-performance mirror coating

- Very high broadband reflectivity in the visible for

s&p-polarized light - Wide range of angles of incidences

- Low absorption

- High operating temperature (up to 300 °C)

- Low-loss design

Typical Applications

- Laser mirrors

- Laser scanner mirrors

- Projector optics

- Digital camera optics

- Replacement for soft silver mirror coatings

- Alternatives to metal coatings

Related mirror types

- SHR-Series (dielectric mirrors for visible light)

- SHD-Series (cold mirrors)

- SHP Series (silver coated mirrors)

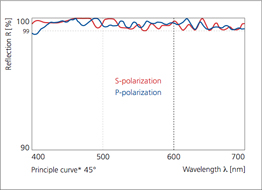

With the SHP-D series, we developed a unique high-performance mirror coating that offers excellent broadband reflection for unpolarized and s&p-polarized light and a wide range of incidence angles. For a 100% dielectric coating, these are unusual characteristics because such kinds of optics are usually designed for only one or a narrow incidence angle range. We achieve these mirror properties with our SHP-D coating system by depositing an extraordinarily high number of thin-film coating layers. The sophisticated broadband coating design allows various applications that are not feasible with metal-based coatings like silver or aluminum mirrors. The SHP-D mirror coating is temperature resistant, so operating temperatures up to 300 °C are possible.

To request our SHP-D high-performance mirror for polarized light with custom dimensions, please choose a thickness in the thickness table or click on the button below.

Request for Quotation

Specifications

SHP-D front surface mirror

Reflectivity

Enlarge the curve to show reflection details

Standard Thicknesses

Please click on a mirror thickness to request a quote.Thickness (mm) |

Tolerance |

|

|---|---|---|

| 1.10 | ±0.10 | ✔ |

| 3.30 | ±0.20 | ✔ |

| The thicknesses marked with "✔" are also available within 48–hour express service. | ||

Reflectivity (i=45°)

- R avg >/= 99.5% at wavelength 420–700 nm

- Rs avg >/= 98% at wavelength 420–700 nm

- Rp avg >/= 98% at wavelength 420–700 nm

- Specifications for other incidences on request

Coating Construction

- Dielectric multilayer coating design

Substrates

- Borosilicate glass

- Selected float glass

- Other substrate materials are available on request

Flatness

- Depending on substrate material and thickness

Surface Quality

- typ. 80-50 scratch & dig (MIL-0-13830A)

- Other on request

Other Specifications

- Abrasion resistance according to MIL-M-13508C

- Adherence according to MIL-C-675C (tape test)

© 1994 – 2026 Präzisions Glas & Optik GmbH

Last update: May 21, 2024