Silver-Coated Front Surface Mirrors

SHP Series

Special Properties

- Protected silver coating

- Broadband and high visible reflection

- Large angle of incidence range

- Virtually no polarization effects

- Low scattering

- Excellent reflection for polarized and unpolarized light

Typical Applications

- Front surface mirror optics for optical measurement and sensor technology

- Fold mirrors in projection systems

- Digital camera mirror optics

- Ophthalmic measurement equipment

- Laser mirrors

- Gold mirror replacement

- Medical devices

Related mirror products

- SEA-VIS-Series (enhanced aluminum mirrors VIS)

- SEA-NIR-Series (enhanced aluminum mirrors NIR)

- SEA-UV Series (protected aluminum mirrors UV-IR)

- SHP-D Series (dielectric mirrors for polarized light)

Our superior-quality silver-metal-coated SHP front surface mirrors feature a high and broadband optical reflection of > 98% for visible light and maintain high reflectivity up to the infrared. Unlike the case with dielectric mirror optics, our optical silver coatings' reflectivity is almost independent of the incident light's polarization.

A pure silver-coated layer is very soft and chemically sensitive, especially to sulfur compounds, grease, and humid atmospheres. For this reason, our SHP mirrors are protected with a dielectric layer on top of the silver coating. The protective coating improves both the mechanical robustness and the corrosion resistance of the mirrors. However, despite the protective coating, front-coated silver mirrors are generally not suitable for harsh environments*.

Thanks to their outstanding reflective properties, our SHP silver metal surface mirrors have established themselves in numerous optical measuring devices and other special applications in technical optics. Compared to aluminum mirrors, they typically offer approximately 2–5 percentage points higher reflection in the red and NIR range, making them the ideal choice for folding mirror applications or multiple deflections in optical systems.

Please use the button below to request a quotation for our SHP front surface mirrors with individual dimensions.

For applications with increased mechanical stress, we have developed our SHP-D mirrors, which offer similar optical properties to our SHP silver front surface mirror but have a less sensitive mirror surface.

Specifications

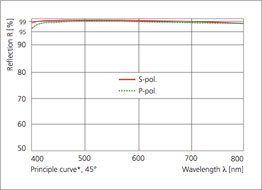

Reflection spectrum

SHP-Silver Front Surface Mirrors

Enlarge the reflection curve of the SHP Silver Mirrors

Standard Thickness

Please click on mirror thickness to request a quote.Thickness (mm) |

Tolerance |

|

|---|---|---|

| 1.10 | ±0.1 | ✔ |

| The mirror thicknesses marked with ✔ are available within our Express Service. | ||

| Custom mirror thicknesses are available on request. | ||

Optical Reflection

- Ravg > 98% @ 420–680 nm, i = 45°

- Highly reflective up to 12 μm

Mirror Coating

- Optical-grade silver coating protected by overcoating

Substrates

- Selected mirror-grade glass

- Custom substrate materials are available on request

Surface Quality

- better than 80–50 scratch & dig (MIL-0-13830A)

- Other surface qualities are available on request

Other Specifications

- Adherence according to MIL-M-13508C,

4.4.6, Tape Test - Hardness according to MIL-M-13508C,

4.4.5, 50 x

If a slightly lower reflection is sufficient for your application, please look at our aluminum front surface mirrors from the SEA series as an alternative.

Handling and cleaning instructions:

Despite their protective coating, silver surfaces should not be touched with bare fingers, as this can cause them to oxidize. Proper cleaning requires non-abrasive methods to ensure that the optical quality of the mirrors is maintained in the long term. We will be happy to provide you with detailed cleaning instructions on request.

All data and specifications given are average guide values and are not guaranteed. Moreover, please consider the “Notes on Specifications”.

© 1994 – 2026 Präzisions Glas & Optik GmbH

Last update: January 06, 2026