RD 50® Radiation Shielding Glass

Monolithic X-ray protection sight-glass with increased lead equivalent

Special Properties

- Increased lead equivalent compared to RD 30®

- High X-ray absorption

- Large dimensions are possible

- More scratch-resistant than acrylic glass

- Non-flammable

- Good transparency

- A wide range of thicknesses is possible

Typical Applications

- X-ray protection glass for medical applications

- Protective windows for positron emission tomography (PET)

- Radiation protection in computed tomography (CT)

- Sight-glass for X-ray rooms

- Radiation protection doors and windows in medical radiology rooms

- Nuclear research

Related glass types

Request for Quotation

RD 50® offers increased absorption of radiation

RD 50® is a clear, transparent, dense flint glass produced by SCHOTT in Germany. The modified lead-silicate glass can shield X-rays and gamma radiation in medical, industrial, and research applications. It has a lead oxide content of > 65% by weight, which results in a density of at least 5.05 g/cm2 and thus enables compliance with statutory safety regulations even at comparatively low glass thicknesses. RD 50® has a higher lead equivalent than RD 30® and therefore offers an increased radiation shielding effect and safety (see table). The X-ray absorption of RD 50® can meet the requirements of the German Institute for Standardization (DIN Germany), European Standardization, and the International Electrotechnical Commission. RD 50® radiation shielding glass's particular composition allows for positron emission tomography (PET) and computer tomography (CT) applications and their combination. RD 50® is also often an adequate solution for shielding applications in nuclear research. The glass is available in a wide range of standard thicknesses. Often, we can polish it to a custom thickness, too. If you are searching for a radiation shielding glass optimized for mammography applications, please visit our RD 30® website.

To request a quote for sight glass or windows made of original SCHOTT RD 50® high-quality radiation shielding glass, please select a thickness from the table in the specifications or click the button below.

Please follow the installation, cleaning, and care instructions for radiation shielding glass.

Specifications

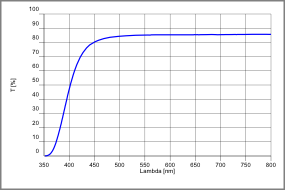

Transmission of RD50®

radiation shielding glass 5 mm thick

Transmission details at 5 mm thickness

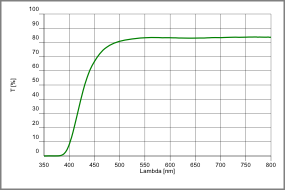

Transmission of RD50®

radiation shielding glass, 20 mm thick

Transmission details at 20 mm thickness

Standard Thicknesses

Please click on a glass thickness to request a quote.Thickness (mm) |

Tolerance |

|---|---|

| 6.0 | ±1.0 |

| 8.0 | ±1.0 |

| 9.5 | ±1.0 |

| 11.0 | ±1.0 |

| 12.75 | ±1.25 |

| 17.5 | ±1.5 |

| 21.5 | ±1.5 |

| Custom thicknesses on request | |

Lead equivalents

| Min. thickness (mm) | 5.00 | 7.00 | 8.50 | 10.0 | 11.5 | 16.0 | 20.0 |

| Tube voltage | Lead equivalent in mm Pb | ||||||

| 76 kV* | 1.5 | 2.1 | 2.6 | 3.0 | 3.4 | -- | -- |

| 80 kV | 1.5 | 2.1 | 2.6 | 3.1 | 3.5 | -- | -- |

| 100 kV | 1.5 | 2.1 | 2.6 | 3.1 | 3.6 | 5.0 | 6.3 |

| 110 kV | 1.5 | 2.1 | 2.5 | 3.0 | 3.5 | 4.9 | 6.1 |

| 150 kV | 1.5 | 2.1 | 2.5 | 3.0 | 3.5 | 4.9 | 6.1 |

| 200 kV | 1.4 | 2.0 | 2.4 | 2.9 | 3.3 | 4.6 | 5.8 |

| 250 kV | 1.4 | 2.0 | 2.4 | 2.8 | 3.3 | 4.7 | 5.9 |

| 300 kV | 1.4 | 2.0 | 2.5 | 2.9 | 3.4 | 4.8 | 6.1 |

| 350 kV* | 1.4 | 2.1 | 2.5 | 3.0 | 3.5 | 4.9 | 6.2 |

| 400 kV | 1.5 | 2.1 | 2.6 | 3.1 | 3.6 | 5.0 | 6.4 |

| 450 kV* | 1.5 | 2.1 | 2.6 | 3.1 | 3.6 | 5.1 | 6.5 |

| 500 kV* | 1.5 | 2.2 | 2.7 | 3.2 | 3.7 | 5.2 | 6.6 |

| 550 kV* | 1.5 | 2.2 | 2.7 | 3.2 | 3.7 | 5.3 | 6.7 |

| 600 kV* | 1.6 | 2.2 | 2.7 | 3.3 | 3.8 | 5.4 | 6.8 |

| 650 kV* | 1.6 | 2.2 | 2.8 | 3.3 | 3.8 | 5.4 | 6.9 |

| 750 kV* | 1.6 | 2.3 | 2.8 | 3.4 | 3.9 | 5.5 | 7.0 |

| 1000 kV* | 1.6 | 2.4 | 2.9 | 3.5 | 4.0 | 5.7 | 7.3 |

| *no tube voltage according to DIN EN 61331-1 | |||||||

Refractive Index

- nD = 1.79

Mechanical Properties

- Density: ≥ 5.05 g/cm3

- Young's modulus E: 56.6 kN/mm2

- Poisson number µ: 0.245

- Torsion modulus G: 22.7 kN/mm2

- Knoop hardness HK 0.1/20: 360

- Stress optical coefficient C

in 1.02 × 10-12 m2/N: 0.78

Thermal Properties

- Mean linear coefficient of thermal expansion:

7.4 × 10-6/K (20 °C ; 300 °C) (static measurement) - Transformation Temperature Tg: 467 °C

- Viscosities and corresponding temperatures:

- Strain point (1014.5 dPa): 444 °C

- Annealing point (1013 dPa): 467 °C

- Softening point (107.6 dPa): 603 °C

- Forming temperature (106 dPa): 673 °C

- Forming temperature (105 dPa): 729 °C

- Forming temperature (104 dPa): 800 °C

- Mean specific heat capacity cp:

0.39 J/(g × K) (20–100 °C) - Thermal conductivity: 0.62 W/(m × K) (at 50 °C)

Chemical Properties

- Hydrolytic resistance according to DIN ISO 719:

- Hydrolytic Class HGB 1

- Equivalent of alkali (Na2O) per g of glass grains: 24 μg/g

- Acid resistance according to DIN 12 116:

- no data available

- Alkali resistance according to DIN ISO 695:

- Alkali Class A3

- Surface weight loss after 3h:

510 mg/dm2

Please make sure to observe the installation, cleaning, and maintenance instructions for radiation shielding glass.

© 1994 – 2025 Präzisions Glas & Optik GmbH

Last update: March 19, 2025