EAGLE XG® – Alkali-Free AMLCD glass

Alkaline earth boro-aluminosilicate composition

Special Properties

- Alkali-free glass composition*

- Low micro-roughness

- Similar expansion coefficient to silicon

- A high strain point allows for increased process temperatures

- Contains no heavy metals

- Display-grade surface quality

- High dimensional stability

- Excellent clarity

- Increased chemical durability

- Low specific weight

- Outstanding electrical properties

- Can be processed by cutting, grinding, and polishing

Typical Applications

- Wafer-level optics

- Modern LCD technology

- Glass wafers for the semiconductor industry

- Thin glass windows

- High-resolution displays

- Active Matrix Liquid Crystal Displays (AMLCD)

- Electronic packaging

- Substrate for optical coatings

Related glass types

- EAGLE2000 Alkali-free boro-aluminosilicate glass from CORNING®

- 1737F Alkali-free aluminosilicate glass from CORNING®

- AS 87 eco Ultra-thin aluminosilicate glass from SCHOTT

- AF 32® eco Alkali-free alumina-borosilicate thin glass from SCHOTT

Request for Quotation

![]() 48-hour express service

48-hour express service

EAGLE XG® is an alkali-free alkaline earth boro-aluminosilicate glass made by CORNING®. It is a perfect material for the fabrication of wafer-level optics. The high-quality glass is produced by a unique fusion draw process, resulting in excellent flatness, smoothness, surface quality, and low nominal thickness tolerance. Due to its high material quality, EAGLE XG® is also ideal for the manufacturing of glass wafers and as a substrate for optical coatings.

EAGLE XG® glass offers exceptional dimensional stability, high chemical durability, and outstanding clarity. It provides all the features required for the manufacturing of modern LCD (AMLCD) and other advanced display technology. The thermal coefficient of expansion (CTE) of EAGLE XG® glass closely aligns with silicon, enabling a wide range of sophisticated semiconductor applications. Moreover, glass has been optimized for an increased strain point, allowing improved fabrication processes at higher temperatures.

EAGLE XG® is also an exciting material for scientific applications. The very low micro-roughness of the glass surfaces allows for special research projects that are impossible with most other glass materials.

EAGLE XG® is considered environmentally friendly because the glass does not contain heavy metals such as arsenic, barium or antimony.

To request a quote for custom-sized EAGLE XG® substrates or windows, please click the button below or select a thickness from the table.

*The total alkali content is approximately 0,1 weight-%.

(Typical < 0.05 weight-%)

Specifications

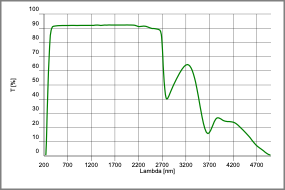

EAGLE XG® transmission

at 0.7 mm glass thickness

Enlarge the curve fto view more details

Additional Transmission Curves

at 0.30 mm glass thickness:

at 0.70 mm glass thickness:

at 1.10 mm glass thickness:

EAGLE XG® standard glass thicknesses

Please click on glass thickness to start a request:| Thickness (mm) | Tolerance | |

|---|---|---|

| 0.30 | ±0.02 | ✔ |

| 0.70 | ±0.02 | ✔ |

| 1.10 | ±0.02 | ✔ |

| The thicknesses marked with "✔" are also available within our 48-hour express service. | ||

| More glass thicknesses (0.2 mm, 0.21 mm, 0.25 mm, 0.4 mm, and 0.5 mm) are available on request if sufficient quantities are needed. Please send us your inquiry in case of need. | ||

Optical Specifications

- Abbe constant: 62.7

- Birefringence constant: 331 (nm/cm)/(kg/mm2)

| Refractive index numbers | ||

|---|---|---|

| Designation

|

Wavelength (nm)

|

Refractive Index

|

nF' |

480 |

1.5159 |

nF |

486.1 |

1.5154 |

ne |

546.1 |

1.5119 |

nd |

587.6 |

1.5099 |

nD |

589.3 |

1.5097 |

632.8 |

1.5082 |

|

nC' |

643.8 |

1.5077 |

nC |

656.3 |

1.5073 |

850 |

1.5028 |

|

940 |

1.5013 |

|

980 |

1.5007 |

|

1000 |

1.5004 |

|

Mechanical Specifications

- Density: 2.38 g/cm3

- Young's modulus: 73.6 GPa

- Poisson's ratio: 0.23

- Shear modulus: 30.1 GPa

- Vickers hardness (200 g load): 640 kgf/mm2

- Fracture toughness 0.89 MPa × m0.5

Thermal Properties

- Coefficient of expansion (CTE) as-formed (ppm/°C):

- 3.4 (0–300 °C)

- 3.4 (20–260 °C)

- Viscosities:

- Softening Point (107.6 dPa): 971 °C

- Annealing Point (1013 dPa): 722 °C

- Strain Point (1014.5 dPa): 669 °C

| Thermal Conductivity (specific heat × thermal diffusivity × glass density) |

|||

|---|---|---|---|

Temperature (°C) |

Specific heat (J/kg×K) |

Diffusivity (cm2/sec) |

Conductivity (W/m×K) |

25 |

768 |

0.0060

|

1.10 |

100 |

896 |

0.0057

|

1.22 |

200 |

998 |

0.0055

|

1.30 |

300 |

1067 |

0.0053

|

1.35 |

400 |

1110 |

0.0052

|

1.38 |

500 |

1154 |

0.0052

|

1.42 |

Chemical Capabilities

- Weathering: Class 1

Weathering is defined by atmospheric-borne gases and vapors such as water and carbon dioxide. A glass rated 1 will rarely show weathering effects. Those rated 2 will occasionally be troublesome, particularly if weathering products cannot be removed. Glass types rated 3 require the most careful consideration.

| Chemical Durability | ||

|---|---|---|

| Solution | Reaction time/

Temperature |

Weight loss

(mg/cm2) |

| HCl – 5% | 24 h at 95 °C |

0.79 |

| HNO3 – 1M | 24 h at 95 °C |

0.49 |

| HF – 10% | 20 min. at 20 °C |

5.18 |

| NH4F:HF – 10% | 20 min. at 20 °C |

0.84 |

| 1HF:10HNO3 | 3 min. at 20 °C |

1.48 |

| 1HF:100HNO3 | 3 min. at 20 °C |

0.16 |

| DI H2O | 24 h at 95 °C |

0.00 |

| Na2CO3 - 0.02N | 6 h at 95 °C |

0.16 |

| NaOH - 5% | 6 h at 95 °C |

1.83 |

Electrical Properties

| Dielectric Constant & Dissipation Factor | ||

|---|---|---|

Frequency (GHz) |

Dielectric Constant |

Loss Tangent |

0.1 |

5.28 |

0.002 |

1 |

5.30 |

0.002 |

2.5 |

5.18 |

0.004 |

10 |

5.14 |

0.008 |

15 |

5.14 |

0.008 |

24 |

5.14 |

0.009 |

60 |

5.11 |

0.011 |

70 |

5.11 |

0.013 |

| Volume Resistivity (25–500°C) | |

|---|---|

Temperature (°C) |

Log10 Volume Resistivity

(Ω-cm) |

25 |

22.92 |

250 |

12.98 |

350 |

10.87 |

500 |

8.72 |

Other Specifications (0.5 mm thickness)

- Dielectric strength: 217 kV/mm

- Breakdown voltage: 107 kV

EAGLE is an acronym for "Enhanced Attribute Glass for Large-Area Electronics". The XG in the product name stands for "extra green".

Other CORNING® materials in our extensive delivery program are EAGLE2000, 1737F, 7059, PYREX®, MACOR®, and ULE®. For further technical details, please feel free to send an information inquiry.

All data and specifications given are average guide values and are not guaranteed. Moreover, please consider the “Notes on Specifications”.

© 1994 – 2025 Präzisions Glas & Optik GmbH

Last update: December 8, 2025